Separation Challenges of Turning PET Resin to Bottles to Flakes Then Back to Bottles

This article focuses on increasing the use of recycled raw material and more specifically recycled plastic water bottles (rPET).

August 15, 2023

Michael Wilks, global marketing director, Bunting

Raw material shortages are on the increase and as consumption increases, the material shortage gap grows wider. It took a pandemic to open the eyes of most producers as to how fragile the supply chain really is. Yet, many powder and bulk operations could do more to alleviate the shortage issue.

There are a number of reasons as to why there may be a material shortage. Some are controllable and some are simply beyond our control. Within the powder and bulk industry, shortages can happen with materials coming in from suppliers and materials going out to customers. Either one could be disruptive enough to put a company out of business.

In this article, we will focus on increasing the use of recycled raw material and more specifically recycled plastic water bottles (rPET). When it comes to sustainability, no other industry gets the scrutiny that the plastic water bottle gets. Plastics recycling starts off as a dirty process in the municipal recycling facility (MRF). There, various items are sorted both manually and mechanically, with a heavy emphasis on plastics. Plastic bottles are split out and baled for transport to a plastics recycling facility. There, the bales are broken apart and the bottles are sorted between clear and green. The sorted plastic is then sent into a shredder or grinder that reduces the bottle into plastic flakes or pellets and, as in most any grinding or shredding process, there will be some metal contamination that is commingled with the rPET.

Magnetic separators do a great job of effectively and efficiently removing ferrous metal contaminants with absolutely no loss of product, or at least no loss that wasn’t preventable. Magnets physically hold the ferrous metal contaminant until it is removed or stripped off the magnet either manually or mechanically. With today’s high-strength neodymium magnets, there is no reason that any ferrous metal contamination should make it past the magnetic separator.

What about the non-ferrous metal contaminants like stainless steel or aluminum that are non-magnetically receptive. The best choice for removal of these particles is to use a metal detector in combination with some type of reject mechanism. Reject mechanisms can be programmed to operate efficiently, but no matter how efficiently they are programmed, there will be some non-ferrous metal particulate that makes it through the reject process. The orientation of the contaminant within the rPET flake, the size of the contaminant, and the settings on the metal detector all play a part in catching the contaminant. Now for all practical purposes we might say the rPET is 92% clean of metal contamination.

So, 92% may sound good to the recycler, but the bottling company that is looking to buy that rPET needs it to be 99.9% free of any metal contamination. After all, the rPET is a ground up plastic bottle that is going to be remade into another plastic bottle and what bottling company would want to risk having a consumer find a shard of stainless steel from a shredder blade, embedded in the bottom of their water bottle?

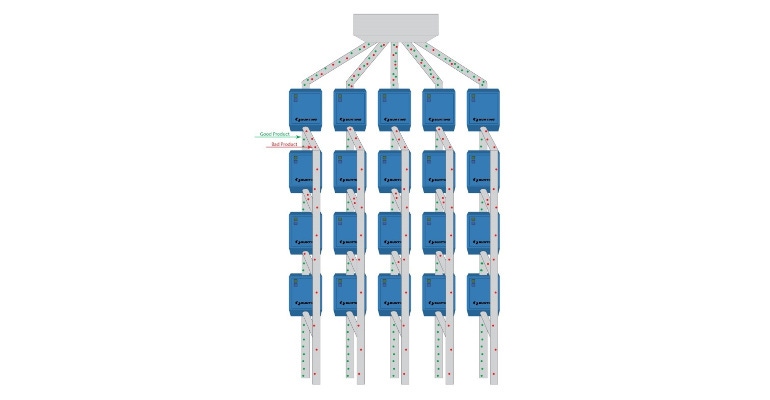

To salvage a rejected bottle that is recycled into material used to make a new bottle is a complicated process that requires a highly purified recycled product. Today, we are seeing a growing trend in the use of a waterfall stack of metal detectors to remove metal contaminants from rPET. As more plastic flake/pellet material coming from plastic bottles gets recycled into new plastic bottles, the need for purity is magnified. How is that accomplished? Let’s say that with one pass through a metal detector the recycler can reject 92% of metal contaminants. That 92% pure rPET then gets passed through a second time which increases the catch rate to 96%. Then through a third time for a 98.9% catch rate. Each additional pass results in a small amount of rejected material loss but the purity level of the rPET that has made it through the system is nearing the targeted purity rate of 99.9% metal free that the bottling company has specified.

Sounds slow, repetitive, and expensive. It does not have to be with a system designed for that specific purpose. By stacking multiple metal detectors on top of the next, the purity rate of the product flow is improved mechanically. But will multiple metal detectors for that purpose generate a reasonable payback? That depends on the flow rates, the types of metal detectors, and what level of monitoring needs to be done. If the flow rate going through the detectors is significant, say at the level needed to supply 30, 40, or 50% of the PET needed by an injection molding operation to make the parisons or “pre-forms” the bottling plant needs, that is a significant amount of plastic that does not end up in landfills or polluting our natural resources. Is there really a market for that much rPET that came from a used PET bottle? As mentioned before, the sustainability of plastic bottles is under fire today from all directions, as consumers push for a sustainable package.

PET bottles are here for the long run but the pressure from consumers, ecologists, and environmentalists to make PET bottles more of a sustainable packaging, is growing rapidly. There exists a market for clean rPET today but the initial collection channel through municipalities is strained due to labor costs and availability constraints. Some markets have become driven by the concept of reusing PET bottles to make new PET bottles one-for-one and those markets have instituted a variety of deposit return schemes (DRS) to get sorted bottles returned for recycling. In some countries, even the bottling companies themselves have created their own DRS. In the US there are currently 10 states that have implemented “bottle bills” that cover plastic bottles and the “Container Recycling Institute” has a “Bottle Bill Resource Guide” at www.bottlebill.org.

It should be noted that no national bottle bill exists in the US. But there are multiple efforts to pass legislation and it is just a matter of time before a national plastic bottle program gets enacted. When such a program exists, the market for recycled PET bottles will have a clean and steady supply. It will be up to the recycler who turns the bottles into flakes/pellets to meet the standard for separation established by the bottler.

If you are a processor of recycled PET content and you would like to see whether you could benefit from a stacked system of metal detectors, run a test on your own equipment by repeatedly recycling your raw material through your metal detector, weigh and track the volume of metal contamination with each successive pass until you reach your own established target level. You can verify your results by sending a similar sampling of the raw material to your OEM for testing. You can even ask for a live demonstration.

Michael Wilks is the global marketing director for Bunting, a global leader in the manufacturing and distribution of magnetic separation equipment and metal detection systems. For more information, email [email protected], call 800-835-2526, or visit buntingmagnetics.com.

You May Also Like