3D printing plus magnets equals patient-specific medical devices

The vast potential of 3D printing patient-specific medical devices can be a real game changer when it comes to pediatric devices. Because pediatrics is a relatively small market, medical technology companies typically do not devote a great deal of R&D into developing products for children. As a result, adult-sized devices are used to treat much smaller anatomies, with predictable results. Now, researchers at Northeastern University (Boston) have developed an innovative 3D-printing technology that uses magnetic fields to shape composite materials into patient-specific products.

November 4, 2015

The vast potential of 3D printing patient-specific medical devices can be a real game changer when it comes to pediatric devices. Because pediatrics is a relatively small market, medical technology companies typically do not devote a great deal of R&D into developing products for children. As a result, adult-sized devices are used to treat much smaller anatomies, with predictable results. Now, researchers at Northeastern University (Boston) have developed an innovative 3D-printing technology that uses magnetic fields to shape composite materials into patient-specific products. The fabrication of appropriately sized catheters for children, and specifically premature babies, is one of the primary applications.

|

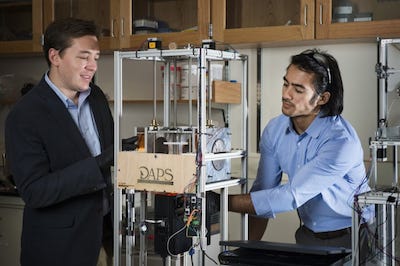

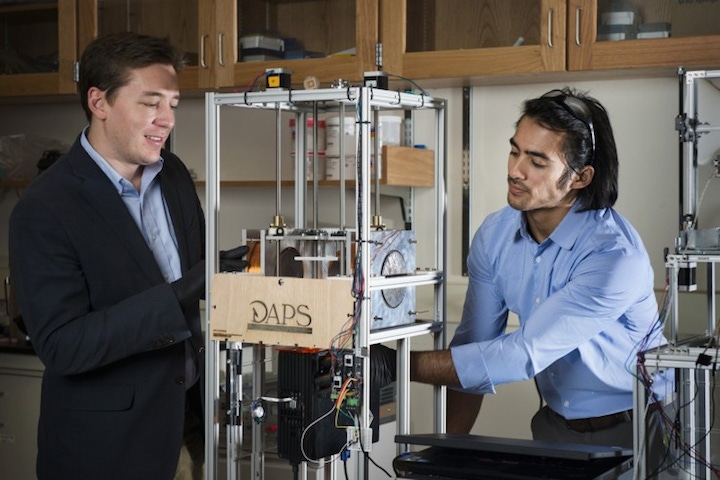

Northeastern University Assistant Professor Randall Erb and doctoral |

Nearly 500,000 premature babies are born each year in the United States, and catheters are used to provide them with oxygen, nutrients, fluid and medications. However, catheters only come in standard sizes and shapes, which means they cannot accommodate the needs of all premature babies. "With neonatal care, each baby is a different size, each baby has a different set of problems," said Randall Erb, Assistant Professor in Northeastern's Department of Mechanical and Industrial Engineering. "If you can print a catheter whose geometry is specific to the individual patient, you can insert it up to a certain critical spot, you can avoid puncturing veins, and you can expedite delivery of the contents," he explains in a news release published on the university website.

The technology developed by Erb's team aims to produce catheters and other biomedical devices that are both stronger and lighter than current models while providing a custom fit. A paper on the new technology appears in the Oct. 23 issue of Nature Communications.

Following nature's lead in medical device design

Although composite materials have been used in 3D printing before, the technology developed at Northeastern allows researchers to control how the ceramic fibers are arranged and, thus, control the mechanical properties of the material itself, explains Joshua Martin, a doctoral candidate who participated in the project. That control is critical because the corners, curves, and holes in a patient-specific device must be reinforced by ceramic fibers arranged in a precise configuration to make the device durable. This biomimetic process is inspired by natural composites found in everything from bones to trees.

"We are following nature's lead," explains Martin, "by taking really simple building blocks but organizing them in a fashion that results in really impressive mechanical properties." Using magnets, Erb and Martin's 3D-printing method aligns each minuscule fiber in the direction that conforms precisely to the geometry of the item being printed.

"I believe our research is opening a new frontier in materials-science research," says Martin. "For a long time, researchers have been trying to design better materials, but there's always been a gap between theory and experiment. With this technology . . . we can theoretically determine that a particular fiber architecture leads to improved mechanical properties and we can also produce those complicated architectures."

Fellow researcher Erb has received a $225,000 Small Business Technology Transfer grant from the National Institutes of Health to develop the neonatal catheters with a local company. Erb is also working on the design of surgical implants using calcium phosphate fibers and biocompatible plastics.

About the Author(s)

You May Also Like