Medical implants drive growing demand for ultra-high molecular weight polyethylene

A study from Technavio (London) projects a compound annual growth rate for the material of more than 9% during the 2017 to 2021 forecast period. Medical applications accounted for almost 30% of market share in 2016.

October 12, 2017

Demand for ultra-high molecular weight polyethylene (UHMWPE) for the fabrication of orthopedic and cardiovascular implants is driving growth for the material in global markets, according to a report from Technavio (London). The study projects a compound annual growth rate of more than 9% during the 2017 to 2021 forecast period.

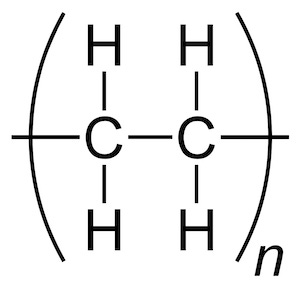

UHMWPE is an odorless, tasteless and nontoxic polyethylene (PE). It has all the characteristics of high-density PE, but with the added advantage of being resistant to acids, alkalis and other organic solvents, according to Technavio. UHMWPE is available in many shapes and forms, making it suitable for a range of applications, but the medical segment is one of the primary markets, accounting for almost 30% of market share in 2016. The other leading applications are protective apparel and gear and rechargeable batteries.

UHMWPE-based implants have gained popularity in applications such as orthopedic and cardiovascular implants, notes the report, because of the material’s long life span and tensile strength. In cardiovascular devices, UHMWPE fibers are gradually replacing polyethylene terephthalate fibers owing to their small size and flexibility, explains Mohd Shakeel Iqbal, a lead plastics, polymers and elastomers research analyst at Technavio. “The types of UHMWPE-based cardiovascular implants are cardiac stents, pacing devices and structural cardiac implants. In addition, the advances in medical technologies, increasing healthcare investments, an aging population and [growing] disposable income” are driving demand for UHMWPE in medical applications, said Iqbal.

The material has a long history of use in protective gear starting with WWII, and it continues to be a popular application. UHMWPE-based hard ballistic fibers are used in helmets and body armor, while soft ballistic fibers are used in vests to protect soldiers from the impact of knives and bullets.

A newer application involves rechargeable batteries, where UHMWPE is widely used as a separator. Demand is especially high in North America, according to Technavio. Separators made from UHMWPE offer a microporous texture, small aperture and enhanced rejection rate, which are crucial for the performance of batteries in the automotive industry in North America.

For a free sample report or to purchase the full study, go to the Technavio website.

About the Author(s)

You May Also Like