August 10, 2023

With the aging population in the United States growing increasingly older, the incidence of cancer and other chronic conditions is not expected to subside any time soon. In turn, there’s been increased demand for products, including plastics, metals, and coatings, produced through bioprocessing methods that can help boost population health while protecting the environment. According to the US Department of Agriculture, biotechnology can be an important tool for achieving healthcare and societal goals, such as reduced poverty and improved global food security, as well as mitigating the causes and consequences of climate change.

Bioprocessing is not without its own consequences and limitations, however. Of particular concern is the presence of oxidative stress, an imbalance of free radicals and antioxidants that reduces the yield of pharmaceuticals and therapeutics produced via bioprocessing by as much as 10 to 15%. A phenomenon caused by an imbalance between the production and accumulation of reactive oxygen species (ROS) in cells and tissues and the ability of a biological system to detoxify these reactive products, oxidative stress can affect several cellular structures, such as membranes, lipids, proteins, lipoproteins, and DNA.

A class of additive unto itself

At Xheme Inc., a specialty materials company based in Newton, MA, that produces additives that help to make plastics and coatings “smarter” by better resisting oxidation, ultraviolet, and microbial growth, researchers and scientists have developed what they say is a programmable non-toxic nanoporous microparticle — the Xheme Multifunctional Additive (XMA) — that significantly reduces or eliminates damage caused by oxidative stress. Also possessing antioxidant and antimicrobial properties, the XMA has landed into a class of additive unto itself with its ability to increase the yield of therapeutics.

“A 50% increase in the yield of therapeutics produced using the XMA additives and XMA-based single-use plastic bioreactors can result in significant savings and saving millions of more lives,” said Dr. SSR Kumar Challa, president, chief scientific officer, and co-founder at Xheme. “Reducing the costs of biomanufacturing to ensure that biologic drugs can reach more patients remains a major challenge. Many biologic therapies cost between $10,000 and $40,000, and some are as costly as $500,000 per year.”

Protecting processes, populations, planet

When incorporated within a plastic film or coating, the additives reportedly protect the surface or contained product from oxidation, corrosion, UV radiation, and bacterial damage. “Unlike the current approach to surface protection, wherein a single additive for a single function is used, the XMA approach uses a single additive with multiple functions,” explains Challa. “This approach reduces the number of additives utilized in both plastics and paints. As many of the current additives are known to cause both human and eco-toxicity, the significant reduction in the number of additives required without compromising on the performance is anticipated to lead to the reduction or elimination of human and eco-toxicity.”

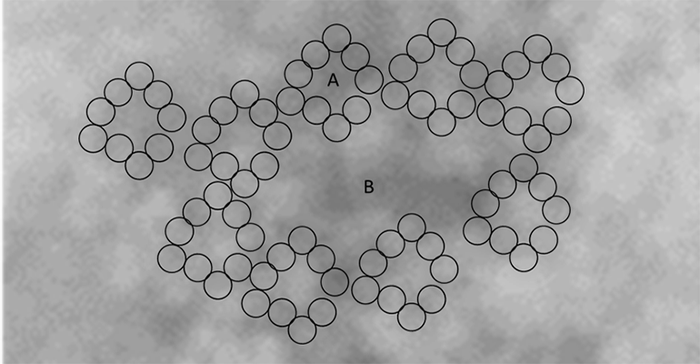

Bi-metallic oxide-based nanoporous macro-structured microparticles that offer a unique bimodal size and porosity distribution (as schematically shown below), XMA additives were found during research to also have the ability to provide protection from free radical damage, peroxides, bacterial contamination, and X-ray radiation. Their superior ability is said to be compared to traditional metal oxide nanoparticles and scavenge reactive oxygen species, according to testing conducted by the Institute for Applied Life Sciences’ Cell Culture Core Facility at UMass Amherst and other labs. But the impact on oxidative stress remains paramount.

|

The different pore sizes of the XMA nanoporous bimetallic oxide macrostructure microparticles. |

Controlling oxidative stress is key in biomedical devices

“Oxidative stress damages all important macromolecules,” said Challa. “Lipid peroxidation, protein oxidation, and DNA fragmentation can lead to multiple cell-signaling effects that can initiate apoptosis. It affects the performance of in vivo and in vitro biomedical devices through the seamless integration of stents, prosthetics, wound healing, blood bags, dialysis bags, and bioprocessing bags. The ability to control oxidative stress with spatiotemporal precision is key to enhancing the performance of both in vivo and in vitro biomedical devices.”

According to Challa, the company’s findings have been especially relevant to the cold storage of red blood cells, which are inherently susceptible to oxidative stress. “This new material design reduced oxidative hemolysis both as free powders when added into human blood in a commercial bag and when incorporated into bioreactor films,” he said. “The XMAs protected against oxidative stress with up to 60 to 70% reduction in experimental oxidative hemolysis observed when the prototype blood bags were exposed to X-rays during storage of up to eight weeks. That is a 60% improvement in comparison with current storage standards.”

Next-gen blood bags

Among the novel applications of XMA today is its application in two types of next-generation blood bags in which the additive replaces the softening agent Di(2-ethylhexyl) phthalate (DEHP), a substance that has come under increased levels of scrutiny because of its various ill effects on health. It reportedly will be banned by the European Union as of 2025.

According to Challa, the first product is a non-DEHP PVC bag and the second is a PVC-free bag. “We are currently scaling up this technology,” he said. “Replacing the toxic plasticizer DEHP in current industry-standard PVC bags with XMA doesn’t compromise the current storage standards or manufacturing methods. The first proof-of-concept results show that the XMA-PVC blood bags reduce oxidative hemolysis significantly beyond the current storage time of 42 days for red blood cells.”

Challa also says that the use of XMA is helping to address other major challenges in the plastics industry — sustainability, toxic products, and complicated supply chain management. “Current anti-UV and anti-corrosion agents are unstable and often toxic,” he said. “Regulatory approvals for antimicrobials are time-consuming and expensive. Coatings and plastics manufacturers are constantly straddling the line between offering environmental, social, and corporate governance–friendly products and known, trusted, and cost-effective products. As programmable multifunctional non-toxic additives, XMAs solve the challenges facing performance plastics, films, and coatings. The bioprocessing bag industry is worth $4.2 billion in 2023 and is estimated to reach about $10 billion by 2028. Companies are increasingly preferring single-use bioprocessing bags as they increase process efficiency and decrease the costs associated with complicated steps such as cleaning, sterilization, and maintenance of steel-based bioreactor systems.”

More broadly speaking, the industry will be able to maintain current performance standards while reducing human and eco-toxicity and decreasing dependency on the increasing number of “single-function” additives that can lead to a greater chemical load on human bodies and the environment, said Challa.

“Additionally, Xheme is working to incorporate further eco-friendly functionality into its additives that would trigger better recyclability, biocompatibility, and biodegradability at the end-of-life cycle of plastics,” he said.

Fortune 500 companies show interest in technology

The multifunctional additives produced by Xheme are also reportedly being tested by several Fortune 500 paint and plastics companies. “We have seven pending patent applications and are currently working on technology validation, scale-up, and obtaining regulatory approvals,” said Challa. “The company’s mission is to bring to market completely non-toxic blood bags and bioprocessing bags that offer the same, or better, performance that protect both people and the planet from toxic additive overload. By providing industries with additives that have multiple abilities, we are working to limit the use of single-use additives and reduce the environmental additive footprint. Our vision is to be a global leader in offering additives that eliminate toxicity and help achieve carbon neutrality without compromising performance.”

About the Author(s)

You May Also Like