New Material Technology for Printable Batteries Spurs Innovation in Healthcare

Wearable medical sensors optimized for patient comfort are among the possible applications.

March 19, 2021

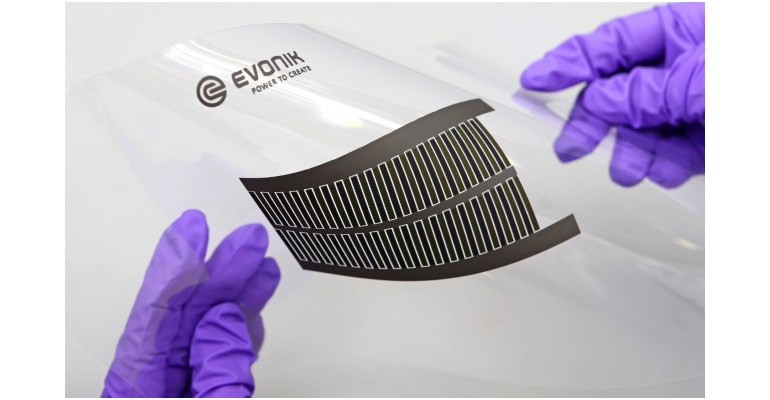

Chemicals company Evonik has developed a new material technology for printable batteries. In collaboration with printed electronics developer InnovationLab, Evonik has demonstrated that the integration of TAeTTOOz technology in printed batteries opens up new applications, notably in healthcare. TAeTTOOz technology is based on the use of redox polymers from Creavis, the strategic innovation unit within Evonik.

Redox polymers can undergo reversible oxidation (loss of electrons) and reduction (gain of electrons) processes, explains a paper on the Royal Society of Chemistry website. Depending on the polymer’s oxidation state, the material exhibits different chemical, optical, electronic, or mechanical properties, write Nerea Casado and David Mecerreyes. “The reversibility and easy external control of redox processes have made redox polymers interesting for different applications and for the development of new electrochemical devices such as organic batteries, electrochromic devices, optoelectronic devices, biosensors, or biofuel cells.”

With TAeTTOOz, Evonik presents an innovative technology for the efficient production of rechargeable battery cells. The new materials can be processed via screen printing into very thin and flexible batteries, giving engineers a high degree of design freedom and making it possible to store electrical energy without using metals.

The printable batteries manufactured with TAeTTOOz technology do not require liquid electrolytes and, therefore, are leak-proof.

“With TAeTTOOz technology, we want to enable new applications,” said Evonik’s Dr. Michael Korell, who is responsible for the development of TAeTTOOz. “Especially with the increasing interconnection of everyday life objects — in the internet of things — the development of a metal-free and printable energy storage solution opens up future areas of application.”

In healthcare, wearable sensors that monitor vital functions can be designed with enhanced user comfort when printed batteries are used. In logistics, sensors powered with printed batteries can also monitor packaging in the supply chain of sensitive goods, including vaccines or food, added Evonik.

About the Author(s)

You May Also Like