Plastic ‘Muscle’ Pumps Up Soft Robotics

New ferroelectric polymer outperforms traditional piezoelectric polymer composites in robotic and medical device applications.

July 11, 2023

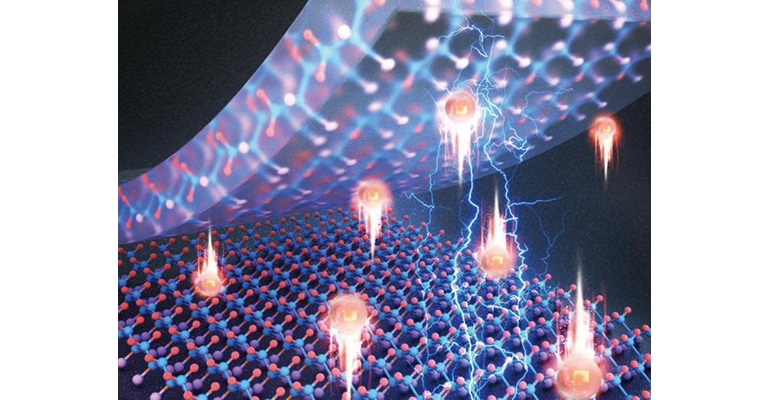

Robots could soon make use of plastic “muscles” thanks to a new ferroelectric polymer that excels at converting electrical energy into motion, according to research led by Penn State.

The research, published in the journal Natural Materials, found that ferroelectric polymer nanocomposites can outperform traditional piezoelectric polymer composites to create high-performance motion controllers. Applications could include advanced robotics, medical devices, and precision positioning systems.

“Potentially we can now have a type of soft robotics that we refer to as artificial muscle,” said study co-author Qing Wang, Penn State professor of materials science and engineering. “This would enable us to have soft matter that can carry a high load in addition to a large strain. So that material would then be more of a mimic of human muscle, one that is close to human muscle.”

Soft actuators enabled by this material could replace traditional rigid materials, allowing for greater flexibility. Actuators change shape when an external force — like an electrical charge — is applied.

However, ferroelectric polymer actuators typically require a very high driving field to enact shape change. The Penn State-led researchers overcame this obstacle by developing a percolative ferroelectric polymer nanocomposite and attaching it to polyvinylidene fluoride to create a network of poles in the polymer: The result: Shape change was induced with less than 10% of the energy typically needed for ferroelectric phase change.

“This new material can be used for many applications that require a low driving field to be effective, such as medical devices, optical devices, and soft robotics,” Wang said.

About the Author(s)

You May Also Like