Stratasys, Siemens Healthineers Partner to Advance Medical Imaging

The project seeks to transform how medical imaging "phantoms," which ensure the performance of CT scanners, can be used in medical and research applications.

November 27, 2023

At a Glance

- 3D printing

- Medical imaging

- CT phantoms

Polymer 3D-printing pioneer Stratasys announced today that it has entered into a partnership with Siemens Healthineers to advance medical imaging "phantoms" for computed tomography (CT) imaging.

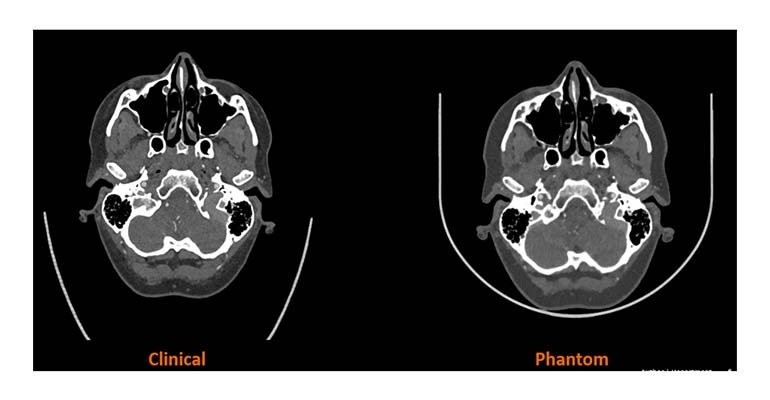

CT phantoms are specialized devices used to evaluate and ensure the performance of CT scanners. By simulating certain characteristics of the human body, phantoms enable the assessment of core metrics, including radiation dose and image quality. They aid in calibration and safeguarding consistent scanner performance. The joint development leverages Stratasys’ PolyJet and RadioMatrix technologies and Siemens Healthineers’ advanced algorithm aimed at translating scanned patient images into specific material characteristics with radiopacity of human anatomy.

PolyJet 3D printing uses photopolymers, UV light, and inkjet heads to produce precise parts. The process starts with a CAD model transformed into a printable format. Drops of photopolymer are jetted onto the build platform and cured with UV lamps to bond layers. Support materials are dissolved or manually removed from the finished PolyJet model.

Introduced last year, RadioMatrix is described by Stratasys as a radiopaque 3D-printing material that allows users to customize models to look like real tissues under x-ray and CT imaging procedures.

The combination of these technologies with Siemens Healthineers’ algorithm reportedly will allow for tailored phantom manufacturing and the creation of ultra-realistic human anatomy characteristics at previously unattainable radiographic accuracy.

The joint project will transform how phantoms can be utilized in the medical field, according to Stratasys. In certain cases, it can enable device manufacturers and academic facilities to replace human cadavers with 3D-printed structures. Having this capability enables critical efficiencies and minimizes inevitable human variability. This work will also produce a critical body of research data, providing key insights for advancing CT system algorithms, driving materials development, and unlocking potential new application areas, as well as identifying future research opportunities, according to the additive manufacturing systems and materials supplier based in Eden Prairie, MN, and Rehovot, Israel.

Beginning with the manufacturing of 3D-printed phantoms for smaller-scale anatomies of the head and neck region, the research will progress to the production of larger, complex anatomies. The Phase One endpoint consists in 3D printing a heart model and entire human torso with complete radiographic accuracy, said Stratasys.

“Knowledge gained from this project provides a breakthrough in medical imaging that will open up new avenues for uses when it comes to 3D printing and imaging,” said Lampros Theodorakis, head of computed tomography product and clinical marketing at Siemens Healthineers. “We are excited about the opportunities ahead of us as a result of this partnership and believe it will have long-term impacts for medical and academic applications.”

About the Author(s)

You May Also Like