New tri-layer medical tubing features improved tensile, burst and elongation properties

A proprietary extrusion process has enabled medical tubing supplier Putnam Plastics (Dayville, CT) to develop an advanced tri-layer tubing technology that markedly improves tensile and burst strength, while reducing elongation. These properties reportedly allow Super-Tri tubing to prevent wire lock-up in catheters when guidewires are used.

February 10, 2016

A proprietary extrusion process has enabled medical tubing supplier Putnam Plastics (Dayville, CT) to develop an advanced tri-layer tubing technology that markedly improves tensile and burst strength, while reducing elongation. These properties reportedly allow Super-Tri tubing to prevent wire lock-up in catheters when guidewires are used.

Wire lock up occurs when the tubing's radial strength is insufficient. "When the catheter balloon is inflated, it can press down on the tubing and lock down the guidewire," explained Ryan Dandeneau, Vice President, who spoke with PlasticsToday from the company's booth (#1801) at the MD&M West/PLASTEC West events in Anaheim, CA. "This is especially problematic in non-compliant (high-pressure) catheters," he added. When wire lock happens during a procedure, the surgeon has no recourse but to remove the device and start over.

There's still time to attend the co-located MD&M West and PLASTEC West events in Anaheim, CA, running through Feb. 11, 2016.

Standard tri-layer tubing, which is often used in percutaneous transluminal coronary angioplasty delivery systems, consists of three distinct polymer layers within one wall: A high-density polyethylene inner liner, which imparts lubricity; a proprietary middle layer for bonding; and a polyamide outer layer. The combination provides strength, trackability and bondability. Super-Tri tubing uses the same material combination but achieves superior performance characteristics. This is a result of the proprietary extrusion process that Putnam has developed.

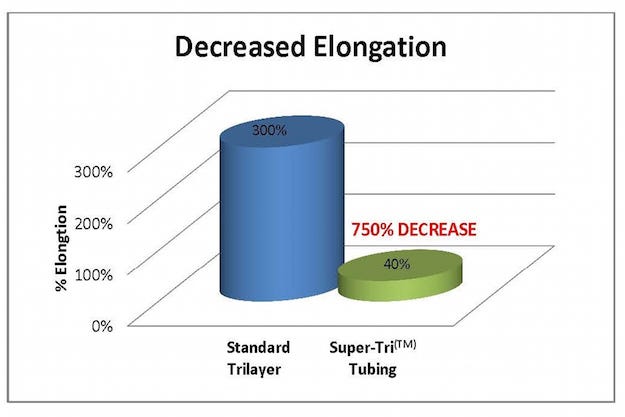

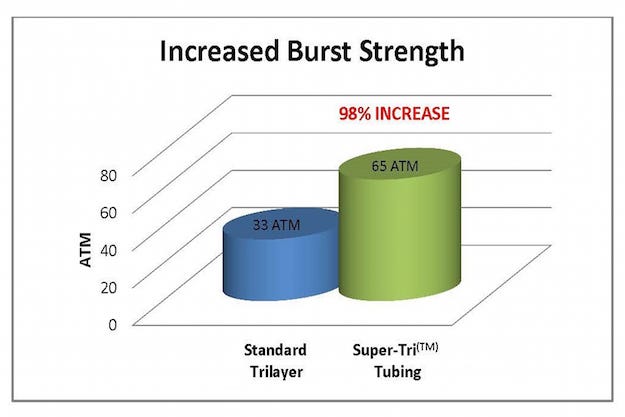

Compared with traditional tri-layer tubing, Super-Tri tubing has decreased elongation by 750% and increased burst strength by 98% (see charts below), making it ideal for balloon catheters requiring high pressure balloons, notes Putnam Plastics. Super-Tri tubing meets the same sizing, tolerances and material configurations as traditional tri-layer tubing, and the properties can be tailored to customer requirements, added Dandeneau.

"A PTCA inner member, where tri-layer tubing is most commonly used, can now be produced with a 130% improvement in ultimate tensile strength and 170% increase in tensile strength at yield," said Bill Appling, Director of Engineering and Assembly. "This product provides new options in the design of catheters for the next generation of devices where strength and size are critical."

Putnam Plastics has supplied medical tubing for nearly three decades with a focus on small diameters used for life-saving vascular catheters and minimally invasive medical devices.

About the Author(s)

You May Also Like