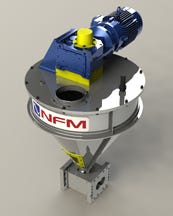

NFM launches Crammer Feeder to process low-bulk-density materials

In need of a crammer/feeder offering high output for low-bulk-density materials and unsatisfied with what it found in the market, extrusion technology supplier NFM (Massillon, OH) designed its own system, which it is now marketing as a standalone product. NFM, which produces wear parts and extrusion systems, including twin- and single-screw extruders, for the compounding, devolatization, and recycling industries, launched its Crammer Feeder at NPE2009.

August 19, 2009

In need of a crammer/feeder offering high output for low-bulk-density materials and unsatisfied with what it found in the market, extrusion technology supplier NFM (Massillon, OH) designed its own system, which it is now marketing as a standalone product. NFM, which produces wear parts and extrusion systems, including twin- and single-screw extruders, for the compounding, devolatization, and recycling industries, launched its Crammer Feeder at NPE2009.

|

During a recent visit by MPW, NFM VP Business Development Paul Roberson said that the new product allows processors to feed low-bulk-density materials like film scrap, foam board/sheet, and carpet fluff into an existing extruder without having to alter screw-flight depth to maintain throughput levels.

NFM says that while processing such low-bulk-density materials can limit the output of single- and twin-screw extruders to a fraction of their nominal output rate, NFM’s Crammer Feeder can improve output so that it approaches pellet-fed rates, while improving the melting stability of a single-screw extruder.

The Crammer Feeder drivetrain consists of a heavy-duty ac motor with up to 25 hp and a direct-coupled right-angle speed reducer, which NFM says provides accurate, yet robust, speed control. The hopper and auger are designed to handle materials regardless of form or density and are manufactured from steel for many years of service-free operation. Standard features include a sight glass and mounting flange to fit an extruder, with made-to-order options including level detector, slide gate, purge valve, swing arm, and vacuum loader. Control options include gravimetric metering, level control, and torque control. NFM has 58-mm twin-screw and 90-mm single-screw extruders available to demonstrate crammer performance with different materials. Three models are available, covering single- and twin-screw extruders from 58 to 176 mm. —[email protected]

About the Author(s)

You May Also Like