Beyond the Pail: Industry-First Hybrid Container Uses 75% Less Plastic

The injection molded pail, which consists of a polypropylene skeletal structure and pre-cut paperboard label, was launched today at the booth of project partner Netstal at Fakuma.

October 12, 2021

Muller Technology, based in Fort Collins, CO, has collaborated with a European packaging manufacturer to develop what it says is the industry’s first hybrid pail. The 24.6-gram injection molded pail, which consists of a polypropylene (PP) skeletal structure and pre-cut paperboard label, uses 75% less plastic than is typically used to mold PP pails of this volume. The 1.2-L Skel-Pac system was launched today at the Netstal booth at the Fakuma trade show in Friedrichshafen, Germany.

The pail, suited for food and industrial packaging, combines strong barrier properties with a more sustainable packaging design, said Muller Technology. Project partner Netstal is molding the pails at booth 5217 in hall B5.

|

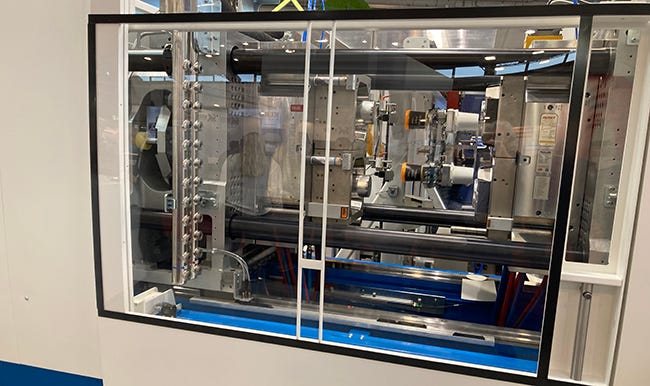

At Fakuma, the hybrid pail is being molded on an Elion 2200-1000 press at the Netstal booth (B5/5217). |

“We take our responsibility as stewards of the environment very seriously and we’re committed to helping our customers meet growing demand for more sustainable packaging,” said Taras Konowal, Director of Sales and Marketing, North America, for Muller Technology. “In response to volatile resin pricing, brand owners and packaging manufacturers are exploring alternative packaging that delivers sustainability benefits and cuts cost.”

Sweden has been ahead of the curve on these sorts of initiatives, added Thomas Federer, Group CEO of Muller Technology Conthey SA in Switzerland, parent company of Muller Technology. "It's also difficult to design sustainable packaging that complies with various recycling programs in different parts of the world," he said from the Netstal booth at Fakuma. The Skel-Pac system, however, represents a substantial step forward in sustainable packaging.

The container has 47 square centimeters of projected area with an L/T (flow length/wall thickness) ratio of 350. A PP-based tamper-evident break-off tab is part of the package The Skel-Pac makes use of Muller’s mold and in-mold labeling (IML) technology, automated case packing using collaborative robotics, and vision inspection system.

The manufacturing system features a two-cavity mold and four-cavity IML base robot, which results in a 4.5- to 5-second cycle time. The hybrid pail offers an attractive shape while excellent printing and design capabilities showcase the brand, said Muller Technology. The new package is commercially available in Germany and brand owners are considering this technology for a range of food and non-food products, according to the company.

Fakuma runs through Oct. 16 at Messe Friedrichshafen.

About the Author(s)

You May Also Like