Interpack Reveals Key Global Packaging Sustainability Trends

The world’s largest packaging trade show lived up to its reputation for showcasing leading-edge technologies — as these new developments in mono-material flexible packaging and paper packaging prove.

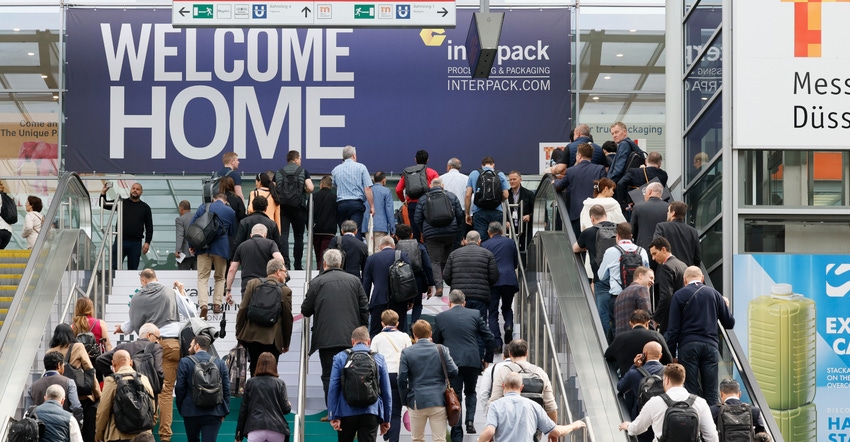

The massive interpack show took place early May in Düsseldorf, Germany. In the six-year gap since last edition (due to the COVID-19 pandemic), packaging has become a central topic for many brands. At the show, 2,800 exhibitors, 140,000 visitors (with one third foreigners), and 18 halls were there to remind the importance of the sector.

As we’ve seen globally, packaging sustainability is a concern for consumers and, often, a headache for many brand owners whom sourcing and end-of-life scenarios for the packaging material have become decisive criteria.

The major packaging producers also have net zero paths to achieve. The European regulations for all packaging in the European Union (EU) to be reusable or recyclable in an economically viable way by 2030 — in line with the EU Green Deal and the EU Circular Economy Action Plan — is putting huge pressure on packaging manufacturers.

Companies of all sizes and across the whole value chain are sharing research and development and joining forces. Collaboration is not just a buzz word; it is helping companies achieve their sustainability goals.

(R)evolution in mono-material films and flexible packaging.

The trend toward mono-material packaging remains obvious.

Jindal Films displayed its new polypropylene (PP) mono-material to help replace polyethylene-based laminates. The global leader in specialty films showcased its Bicor oriented polypropylene (OPP) films designed to facilitate the switch from non-recyclable laminates (that is, containing PET, aluminum/foil, or paper, for example) towards mono-material mechanically recyclable PP-based laminates for flexible packaging markets.

... facilitate the switch from non-recyclable laminates … towards mono-material mechanically recyclable PP-based laminates for flexible packaging markets.

The breakthrough technology Bicor 12MB100 is a high stiffness OPP film with low shrink for broad PET replacement applications to help brands in their “light-weighting” journey. For more specialized applications when designing PP-based retort barrier laminates, Bicor 25MR100 and 25MR103 are being proposed as print outer webs. MR100 and MR103 were designed to help minimize the shrinkage and visual distortion during both the heat-sealing step and the steam autoclave sterilization step.

Since nothing beats a live demo, Jindal organized live tests with 11 industrial machinery partners using PP mono-material solutions on more than 20 packaging machines, covering four commonly used flexible packaging formats — vertical form-fill-seal, horizontal form-fill-seal, overwrap, and pouches (lay-flat and standup). Most of these types of machines were typically previously running non-recyclable structures. These live demonstrations aim to prove the versatility of polypropylene films, with a balance of mechanical, barrier, optical, and heat-seal properties unequalled by other materials.

Another “design for recycling” innovation for sustainable packaging is the oneBARRIER PrimeCycle, a polymer-based mono-material developed by Bobst with several partners. PrimeCycle is an EVOH-free, topcoat-free solution for polyethylene (PE) barrier films that offers an alternative to metallized polyester films. It bears the advantage of being recyclable while retaining barrier qualities. Dow Packaging and Specialty Plastics is the creator of the breakthrough technology. Sun Chemical, a global leader in the production of inks, coatings and adhesives, is the developer of the adhesive for the oneBARRIER PrimeCycle project and one of the co-creators of the primer. Bobst has opened its two huge demo and centers in Europe to all actors to speed up industrial packaging solutions.

A leader in flexible packaging and material science, ProAmpac showcased its new high-performance mono PE recyclable film. Called ProActive Recyclable R-2050, it is its newest patent-pending addition to the ProActive Recyclable series of polyethylene-based structures. Developed for the European market, R-2050 is to replace conventional multi-material laminates without affecting the high-speed filling line efficiencies.

The R-2050 is available in standard and high-barrier versions to maintain or extend the shelf life of food products. Both platforms are widely recyclable in Europe through existing streams, and compliant with OPRL (On-Pack Recycling Label initiative) in the UK for front-of-store drop-off.

Of course, Sabic is also in the run and showcased its Trucircle solutions for flexibles packaging and in particular heat-resistant mono-PE pouches.

Done in close cooperation with Covestro, this new fully recyclable stand-up pouch is made with SABIC BOPE material, including Covestro’s heat-resistant coating resin technology. The transparent coating, currently in trial phase, has been tested and validated, offering a broader sealing temperature window when processing on form-fill-seal lines for flexible packaging as it prevents both film shrinkage and film sticking to heat-seal bars during FFS. Sabic’s BOPE material is available in certified circular and renewable grades.

A few days after the fair, Sabic announced a sector initiative. Together with BASF, Covestro, Dow, LyondellBasell, Mitsubishi Chemical, SABIC and Solvay, they have committed to join R&D projects towards more sustainable plastic waste processing and mechanical and chemical recycling.

Could this be wrapped in paper instead?

Numerous companies displayed recyclable paper pouches.

ProAmpac presented its ProActive Recyclable Paper-1000 for a curbside recyclable and heat-sealable paper packaging also suited for frozen food applications, such as ready-to-eat meals and vegetables. RP-1000 can also be used for some dry foods and secondary packaging applications such as confectionery. Pre-qualified for curbside recycling, RP-1000 can be recycled in both paper (it is adequate for repulpability) and mixed streams.

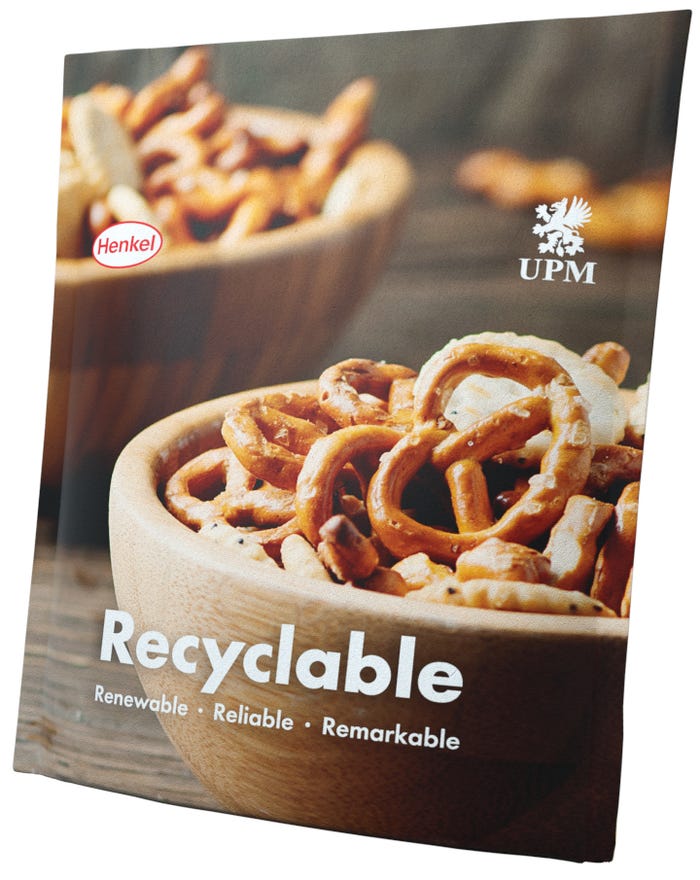

Plastic coating traditionally required for protection and heat-sealing often renders the final product difficult to recycle. So UPM Specialty Papers and Henkel have reworked the concept. Based on existing UPM Asendo and UPM Asendo Pro barrier papers, the water-based coatings LOCTITE LIOFOL HS 2809-22 RE heat seal and AQUENCE EPIX BC 6134 grease barrier are added. The resulting pouches are easy to recycle and contribute to recover more fibers. This helps meet growing consumer and regulatory demands for easy-to-recycle packaging.

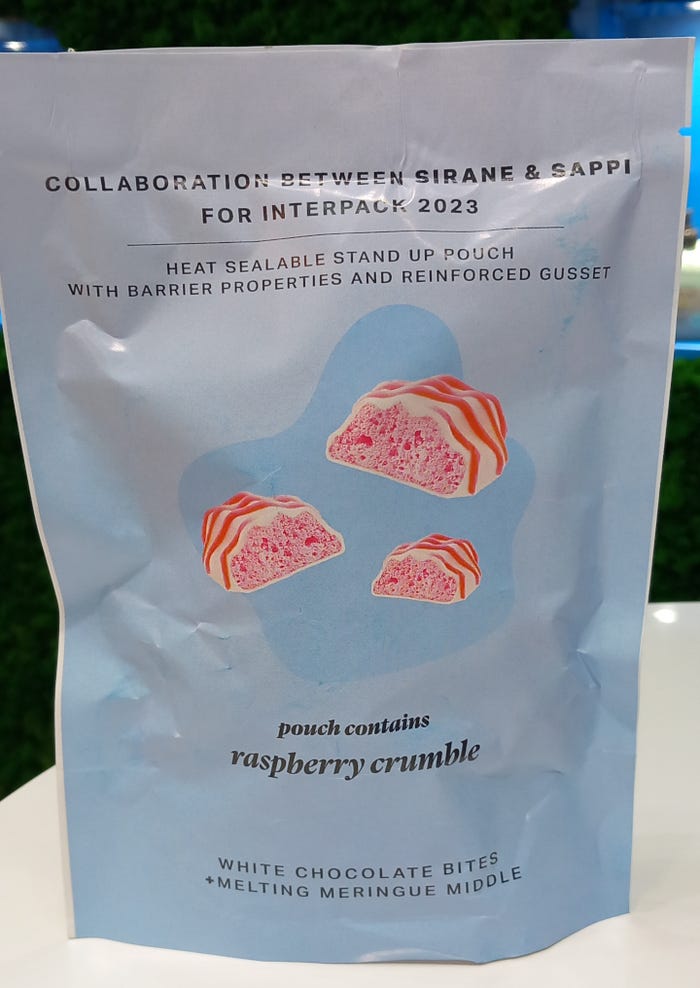

Similar operation for Sappi Group, who joined Sirane for a focus on coated papers as a flexible packaging solution. Leader in packaging development and the largest pouch manufacturer in the UK, Sirane brought its knowledge of packaging and coating with its Earthfilm, which can be supplied as flow-wrap film or pre-formed standup pouches to the giant paper maker Sappi. Together they showcased the heat-sealable standup pouch with barrier and reinforced gusset.

As a proof of its commitment to this new segment, Sappi has recently made a multi-million euro investment in a new type of barrier coating line at its Alfeld mill in Germany. The state-of-the-art solution will be used to produce innovative high-barrier papers.

Claiming to be the inventor of the Dry Molded iber, PulPac is a Swedish packaging company whose process turns cellulose pulp into sustainable, rigid, three-dimensional packaging.

It is called Dry Molded Fiber since very little water is used in comparison with conventional wet molding.

It is called Dry Molded Fiber since very little water is used in comparison with conventional wet molding. Owners of the company are Stora Enso, Amcor, and Aliaxis. Its North American partner is Seismic Solutions based in Chicago, where an application center is facilitating the demo and will allow scaling up Dry Molded Fiber.

Paperdose is produced by Valmatic, an Italian co-packer in thermoforming doses for European and Italian customers. As a testimony of its attention to sustainability and environmental issues, it has developed a range of single-dose packaging of variable capacity ranging from 1 to 50 ml, manufactured with recyclable paper from forests certified by the Forest Stewardship Council (FSC) and with recyclability confirmed by the Aticelca cellulosic recyclability assessment. The mono-dose can be filled on form-fill-seal machines and is targeted at the pharmaceutical and cosmetic sectors.

And finally, Swiss-based packaging manufacturer Hoffmann Neopac is proving that paper tubes are not just a gimmick. The PaperX is a fiber-based laminate that uses up to 80% paper in its production. Compared with conventional tubes, the packaging contains 46% less plastic. You can’t be afraid to innovate if you want to survive in the packaging sector!

About the Author(s)

You May Also Like