PHA bioplastics a ‘tunable’ solution for convenience food packaging

Cambridge Consultants (Cambridge, England) sees a great opportunity for polyhydroxyalkanoates (PHA) bioplastics in convenience food packaging—Catherine Joce, sustainability and circular economy lead, explains why.

A harsh global spotlight on the environmental damage caused by single-use plastics is driving business to reconsider the sometimes ruinous impact of products, processes and packaging.

“For generations there has been a dependency between economic growth and increased resource consumption and emissions,” says Catherine Joce, sustainability and circular economy lead at Cambridge Consultants (Cambridge, United Kingdom). “It doesn’t have to be that way. Businesses across all industries are beginning to realize the potential of innovation to improve both profit and sustainability.”

Bioplastics—plastics that are bio-derived, biodegradable or both—are an increasingly feasible technical alternative to conventional polymers. New industrial processes now mean that bioplastics can be produced from post-consumer content, converting environmentally damaging waste into a valuable resource to be used as a feedstock for these processes.

To date, the use of bioplastics in food service has been limited by technical performance at high temperatures, cost and limited supply. While there has been limited introduction of cups for cold beverages made from polylactic acid (PLA), a bioplastic derived from cornstarch, these are not suitable for hot drinks. Cambridge Consultants evaluated a range of biopolymers and identified materials that are suitable for even the most challenging convenience food applications: polyhydroxyalkanoates (PHA) bioplastics.

PHAs are biodegradable, readily compostable thermoplastics, produced by microbial fermentation of carbon-based feedstocks. The properties of PHA polymers are customizable to the application, depending on the specific combinations of different monomers incorporated into the polymer chain.

To demonstrate the potential of PHA bioplastics in the food service industry, Cambridge Consultants has designed a range of biodegradable plastic products served on a bioplastic tray (shown above), all of which can be conveniently disposed at the point of use. All items are designed to decompose in industrial composting facilities, meaning they can be disposed of alongside food waste—eliminating the need for sorting, washing and separate bins.

If you’d like to read more, see What’s new in PHA bioplastics: An update with Cambridge Associate, published July 2019.

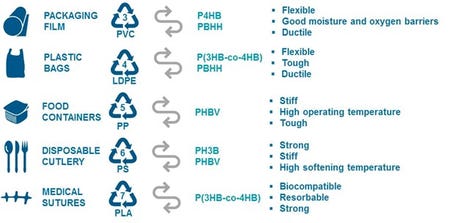

“These could include both food service takeout type products and supermarket-sold products for consumption in the home such as ready meals or coffee pods,” according to Joce. She answers PlasticsToday’s questions in this exclusive Q&A, the first of which she responded with the accompanying infographic (below) that visually summarizes the physical requirements of some common plastic products, the current materials that fulfill these requirements and the PHA types that could potentially replace these traditional materials.

What’s notable about convenience food packaging that it commands Cambridge’s attention?

Joce: Convenience food packaging is a particularly challenging waste stream for end of life management as it is often multi-material (challenging to recycle) and contaminated with food (low value). Convenience food packaging waste is also a highly visible problem to consumers—they often feel guilty about generating waste, but at the same time enjoy the benefits packaging provides.

What is it that makes PHA so uniquely special?

What is it that makes PHA so uniquely special?

Joce: The most exciting feature of PHA is its “tunable” property set. PHA is not one chemical structure, it is actually a whole family of related polymers. So depending on the production process and the feedstocks used, different polymers with different physical properties can be produced. PHAs can either be homopolymers; where only one PHA is used to build the polymer chain, or copolymers; where more than one PHA is employed to build the chain. Typically homopolymers have rather unhelpful mechanical properties that cannot be easily altered beyond the addition of plasticisers, nucleants and other processing aides.

Copolymers on the other hand have properties that can be continuously tuned between a certain range, and often can have properties that are superior than either one of the monomers alone. For this reason it is far more common to find PHA copolymers rather than homopolymers in most applications.

PHA is also the only biopolymer which is produced via industrial fermentation—a process more similar to brewing than the chemical synthesis used to produce most biopolymers. Critically, the most recent developments mean organic waste can be used as a feedstock, reducing dependency on primary crops.

The words “challenging food applications” that you mention: that represents what range of conditions and temperatures?

Joce: Beverage applications require polymers that maintain their properties when in contact with liquids up to 100 deg C/212 deg F. Microwave could require even higher temperatures above 160 deg C/320 deg F.

What does “design” involve specifically in this statement: “Cambridge Consultants has designed a range of biodegradable plastic products, all served up on a bioplastic tray”?

Joce: Cambridge Consultants have undertaken desk-based technical feasibility to evaluate which specific PHA polymers could meet the challenging temperature requirements for hot food and beverage service applications such as coffee pods. Using materials data and computer aided design (CAD) modelling we have produced 3D renderings of the items. The next stage will be to produce prototype products.

Can you provide more details on the range of biopolymers studied?

Joce: We evaluated common biopolymers such as PLA and PBS which tend not to perform well at high temperature and looked in detail at the various commercially available PHAs (P4HB, P(3HB-co-4HB), PHBV, PH3B, PBHH, etc.).

When does biodegradability make better sense than recycling?

Joce: End-of-life considerations are important when considering which applications are suitable for designing with PHA. PHA products can either be designed to enter the natural environment (e.g. mulching films ploughed back into the soil) or to be treated in industrial composting facilities. Care must be taken not to contaminate existing recycling systems for conventional polymers; for this reason PHAs would not be suitable replacements for PET water bottles.

What’s possible now with bioplastics and what’s foreseeable in the future?

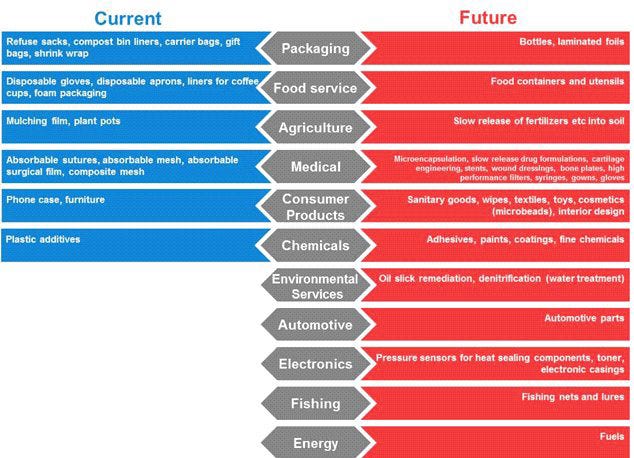

Joce: The versatility of PHAs lends them to a wide range of potential market applications. The main markets where PHAs have already achieved some penetration are packaging, food service, agriculture and medical products. PHAs are penetrating in both low value, high volume markets such as compost bin liners as well as low volume, high-value markets such absorbable surgical film.

What’s the takeaway for our readers?

Joce: Polyhyroxyalkanoates (PHAs) are a class of bio-derived, biodegradable polymers which could replace conventional polymers in a range of applications. PHAs provide a tunable property set which provides unparalleled potential for bioplastic substitutes for fossil fuel-derived plastics in a wide range of applications. In particular, the superior high-temperature performance of PHAs significantly extends the addressable number of applications for bioplastics beyond those which can be served by the most common bioplastic PLA.

With costs now approaching parity with conventional polymers, overcoming manufacturing challenges is the last major hurdle preventing wide-scale adoption of PHAs.

About the Author(s)

You May Also Like