Placon’s OxyStar Brings Sustainability to Barrier Packaging

The PET-based oxygen-barrier material is the first to carry a #1 recycle symbol, allowing it to enter the PET recycling stream.

February 4, 2021

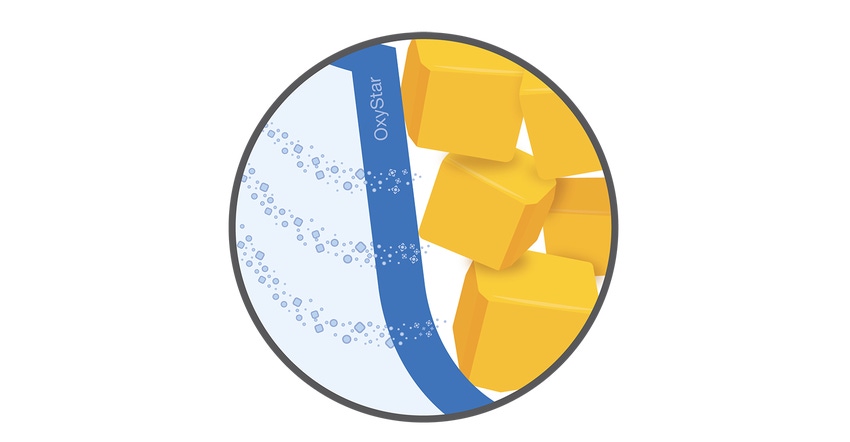

Sustainable thermoformed packaging supplier Placon Corp introduced its patent-pending recyclable oxygen-barrier material, OxyStar. Direct oxygen contact with perishable foods is known to significantly decrease the shelf life of oxygen-sensitive products, increasing food waste and shrinking profits for producers, said Placon. “OxyStar is the world’s first recyclable PET barrier material,” added the company.

Most barrier solutions today are classified as #7 in recycling symbology, which designates a material that cannot be recycled. OxyStar PET barrier material has a #1 recycle symbol, allowing the package to be put back into the PET recycling stream for repeated use. “Creating a package that gives your products a better way to stay fresher for longer and increases product shelf life while making a sustainable impact is how we simply make better packaging,” said Placon.

Placon’s OxyStar barrier material uses an active barrier that stops oxygen ingress through a free radical chain reaction within the packaging sidewalls. Throughout the shelf life of the OxyStar active agent, oxygen ingress will be near zero.

“Our OxyStar PET barrier material is bringing a sustainable solution to the barrier-packaging space that we have not seen before,” said Brian Hodek, Placon Food Processor Sales Manager. “Being able to create a barrier-packaging solution that uses the #1 recycle symbol to maintain a closed-loop stream helps support our mission and vision as a packaging company. This barrier application took significant time to develop, but our team has already started working with key customers across the United States and we anticipate many more customers inquiring about OxyStar as we start developing new custom food packaging in the coming months.”

In addition to its Madison, WI, headquarters, the company has thermoforming operations in West Springfield, MA; Elkhart, IN; and Plymouth, MN.

About the Author(s)

You May Also Like