Phoenix Technologies launches new melt-form rPET pellet for bulk handling packaging applications

Phoenix Technologies International, a producer of recycled polyethylene terephthalate (rPET), is announcing the availability of its latest resin grade. The announcement is expected to open the door for additional, larger commercializations of rPET bottles and containers for a wide variety of food, beverage and other applications.

February 24, 2015

Phoenix Technologies International, a producer of recycled polyethylene terephthalate (rPET), is announcing the availability of its latest resin grade. The announcement is expected to open the door for additional, larger commercializations of rPET bottles and containers for a wide variety of food, beverage and other applications.

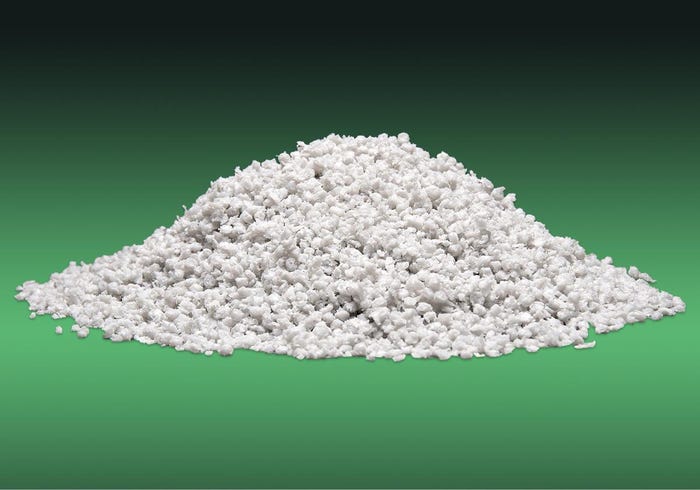

LNO c melt-formed pellet has been engineered to withstand bulk handling and transport, while still providing the desired color and low acetaldehyde attributes found in the original compacted formulation. It is also Food & Drug Administration approved for conditions of use A-J.

The company's original LNO c is formed by compacting a fine grind powder. It was designed to provide optimum performance for "through the wall" bottle and container making operations.

The company's original LNO c is formed by compacting a fine grind powder. It was designed to provide optimum performance for "through the wall" bottle and container making operations.

The new LNO c melt-formed pellet has been engineered to handle the rigors of bulk transport for those larger, remote users whose production requires truckload or tanker deliveries.

"We view this as a hybrid product. Users will now get the handling benefits of a melt form pellet, but still retain the great color and low acetaldehyde characteristics of the original compacted resin," said Lori Carson, director of commercial operations. "This means that larger-volume users who have been evaluating the possibility of using rPET to produce containers now will have a new option."

Phoenix' proprietary rPET technology is used at up to 100% content to produce a variety of packaging containers and bottles for food, beverages, pharmaceuticals, shampoos, soaps and detergents.

About the Author(s)

You May Also Like