Plasma treatment versus solvent treatment: surface adhesion improvement for polypropylene car bumpers prior to painting

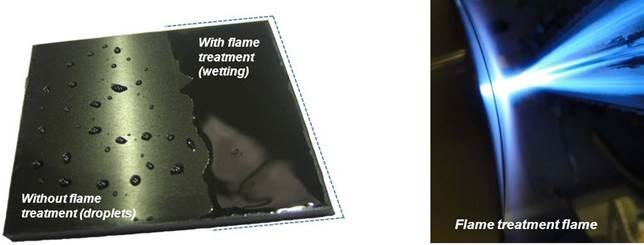

Flame treatment improves the surface adhesion qualities of plastics prior to the application of paints, inks or adhesives. Once a surface is flame treated, coating ability is greatly improved leading to increased durability of the finished surface.

August 20, 2014

Flame treatment improves the surface adhesion qualities of plastics prior to the application of paints, inks or adhesives. Once a surface is flame treated, coating ability is greatly improved leading to increased durability of the finished surface.

|

Plasma-treated surfaces attract liquid coatings, including paint. |

Flame treatment technology is widely accepted by the automotive industry, one prominent example is the use of flame treatment throughout the automotive industry for the surface adhesion improvement of polypropylene car bumper moldings prior to painting. The flame treatment guarantees the paint adherence over 100% of the surface area of the bumper, replacing the use of primers. The high quality demands of the automotive industry and the harsh environment extremes that a car bumper has to endure such as temperature, sunlight, water and impact prove the worthiness of the flame treatment technology.

Surrounding factors for selecting flame treatment are economical and environmental as flame treatment is very low cost to run because the gas cost is very low compared to the use of solvent-based primers and eliminating primers has the benefit of eliminating the associated solvent emissions making the paint process overall much more environmentally friendly.

Aerogens key know-how is the method and techniques of the application of a precisely defined and carefully controlled gas flame to a surface. Flame treatment is quickly applied to the material surface and changes the surface properties, significantly enhancing the materials ability to bond with a coating. In particular the complex combustion chemistry of the flame changes the surface characteristics of the substrate by an increase in the presence of oxygen in the surface, this activated surface attracts the molecules of a liquid coating allowing for the liquid coating to "wet" the surface which in turn allows for good adhesion to take place.

Aerogen is exhibiting at the upcoming Fakuma trade fair Messe Friedrichshafen 14th -18th October 2014 at Hall A6 stand 6513.

This article is an edited version of material supplied by Aerogen (Hampshire, UK). Aerogen designs and manufactures plasma treatment systems in the UK.

About the Author(s)

You May Also Like