Plastics manufacturer creates specialty house to help victims of natural disasters

Like everyone else, the employees of Hahn Plastics watched in horror as Typhoon Haiyan tore through the Philippines. About 130,000 homes were destroyed leaving many without shelter, with 544,606 people displaced and 1,215 evacuation shelters set up. Estimates are that more than 11.5 million people are affected in total.The Manchester-based firm specializing in recycled plastic products wanted to do something, to help not only with the Typhoon Haiyan disaster, but also similar weather-related ones in the future.

January 7, 2014

Like everyone else, the employees of Hahn Plastics watched in horror as Typhoon Haiyan tore through the Philippines. About 130,000 homes were destroyed leaving many without shelter, with 544,606 people displaced and 1,215 evacuation shelters set up. Estimates are that more than 11.5 million people are affected in total.

The Manchester-based firm specializing in recycled plastic products wanted to do something, to help not only with the Typhoon Haiyan disaster, but also similar weather-related ones in the future.

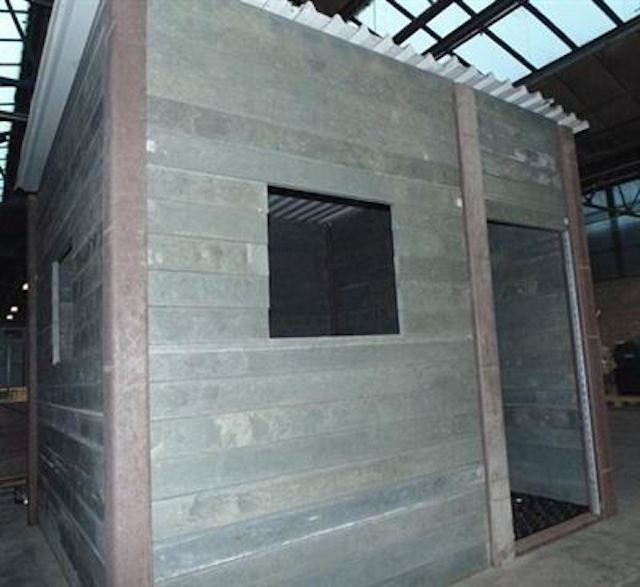

"A colleague who has been working with recycled plastic for years has always felt there must be something that can be done to help those affected by such disasters in areas where their infrastructure is unable to cope," Katie Fairhurst, spokesperson for Hahn Plastics, told PlasticsToday. "Upon hearing about Typhoon Haiyan, he decided to finally put all his thoughts into reality and within a matter of hours we had the Hahn Eco House constructed in the warehouse."

Hahn Plastics produces a variety of recycled plastic garden and park products as well as industrial solutions. In the aftermath of Typhoon Haiyan, the team launched its new project, designing and developing a flat pack house, which the company says can be built with no specialist tools in just a few hours.

Hahn Plastics produces a variety of recycled plastic garden and park products as well as industrial solutions. In the aftermath of Typhoon Haiyan, the team launched its new project, designing and developing a flat pack house, which the company says can be built with no specialist tools in just a few hours.

The Hahn Eco house is 2.8m x 2.8m in size and made up of five supporting beams and 80 wooden profiles. The sides of the house were made from "tongue and groove" boards, which slotted into the supporting beams; these make the houses water and wind resistant as they are interlocking, Fairhurst said. In the prototype the company developed, different lengths were used in order to allow space for a window, which they left open. The roof of the house was simply a sheet-corrugated steel nailed into the top.

For the supporting beams, Fairhurst said they found it's best if they are dug into the ground to achieve maximum strength. Once the supporting beams have been placed into the ground, the tongue and groove boards simply slot in around the infrastructure. With profiles made to measure, no additional work was needed, she said.

The principle behind the house is to replace flimsier shacks that are often made from tin and timber and easily destroyed during natural disasters with something that is sturdier, which can offer shelter and can be quickly erected in the aftermath of events such as hurricanes and typhoons.

"As far as we are aware there is nothing quite like our Hahn Eco House on the market," Fairhurst said. "With the building materials used, it is designed to be a long lasting home for the locals rather than a temporary fix. The shacks that they build themselves now are extremely unstable, therefore allowing for these disasters to cause such devastation time and time again."

The Hahn Eco House is a completely flat pack, which would allow for it to be sent around the world. They hope to get the word out about the Eco House so it can be deployed to the Philippines.

"This is just one idea which we have had, however, with recycled plastic being so versatile, we have made many other finished products from our profiles manufactured here in Manchester, such as retaining wall structures," she said.

About the Author(s)

You May Also Like