An intercontinental cap co-op

A new alliance provides catalog-shopping-like services to bottlers for the latest cap and closure designs.

October 29, 2008

A new alliance provides catalog-shopping-like services to bottlers for the latest cap and closure designs.

A close working relationship has been formed between a product development firm specializing in proprietary, patented closure designs that’s based in the UK and a moldmaker specializing in advanced, high-cavitation tooling that’s based in Ontario to make the latest, most cost-effective capping solutions available to bottlers around the world. StackTeck (Brampton, ON) recently formed a working relationship with Universal Closures (Tewkesbury, UK) that has already resulted in “substantial” new business for StackTeck in high-cavitation cap molds, according to StackTeck’s president, Randy Yakimishyn.

|

“Back in 2007, we saw tremendous potential between our companies, because Universal offers proven plastic closure designs, while StackTeck specializes in tooling for prototype, pilot, and production molds. Our companies work together to prototype and prove out many different cap designs for standard bottle finishes, so our mutual customers can start off ordering production molds with the shortest possible time to market. The result has been increased business, especially for tamper-evident beverage caps, for which we currently have more than 500 cavities in the production pipeline.”

Rod Druitt, Universal Closures’ president, adds, “We’re pleased to be working with StackTeck on a large number of programs, and we find that by working together we can tackle the toughest challenges successfully.”

Included in those tough challenges Druitt mentions are 1881 tamper-evident caps for carbonated soft-drink applications in large-volume production, according to Jordan Robertson, StackTeck’s general sales manager.

Art-to-part allies

“We’re working with them on a range of products,” Robertson says. “We’ll build the prototype mold and qualify the products with Universal. Our cooperative efforts include developing product standards with them for the new 1881 standard for tamper-evident caps, which is slowly becoming the new international standard. The ISBT has been working on this standard for years.”

The 1881 standard created by the International Society of Beverage Technologists (Dallas, TX) involves a new lightweight-thread-finish voluntary specification for 250-ml to 3-liter plastic soft-drink bottles. Robertson says Universal’s lightweight 1881 cap design has been approved for use in bottle sizes up to 3 liters by an undisclosed “major player” in soft drinks.

“The goal is to develop and manufacture closures with a shorter finish that are thinner and more lightweight, providing a closer match to the bottle finish for the latest 28-mm standard beverage bottles incorporating a reduced vertical height and thinner walls—shorter caps for shorter bottle finishes,” says Robertson. “The standard’s been around for a while. Prequalified caps meeting the 1881 standard are critical. We’ve been successful working with Universal in getting their products 1881-qualified.”

Talks between the two companies began last year, and, after finding that their product offerings complemented one another, Robertson says the first public exposure of their coming strategic alliance was at the K 2007 trade show in Germany. “We invited them to the show and used about 25% of our display case to show their cap designs.”

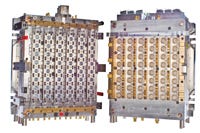

Today, it’s a more closely cooperative effort. “We have Universal personnel on site here in Brampton, and we’ve already designed stack molds with up to 2-by-128 cavities. We can also provide 48-, 72-, and 96-cavity single-face tooling for Universal’s caps, as well as prototype tooling. We’re taking a lot of work coming in from folks who want to quickly get into production.”

In addition to tamper-evident 28-mm PCO, 1881 CSD, and noncarbonated beverage caps, StackTeck will be helping its customers tool up systems for producing other Universal specialties, including:

• Its economical Hinged Molded Closed design—a hinged cap with tamper evidence that’s molded in the closed position.

• Its Flex Spring Hinge cap design for flip-top caps, suitable for a wide range of different applications.

• And its Hinged Sports Closure, which includes an integrated spout plus double-locking tamper evidence.

Through its alliance with StackTeck, Jordan says Universal’s mission is to provide customers with a service akin to catalog shopping for the latest cap designs with zero prototyping requirements.

International Society of Beverage Technologists | www.bevtech.org

StackTeck | www.stackteck.com

Universal Closures Ltd. | www.universalclosures.com

About the Author(s)

You May Also Like