By Design: Tough choices: Balancing cost and shelf appeal

The lowest cost is not always ideal. Packaging is the largest single market for plastic materials. Bottle caps represent a major market for U.S. molders. Threaded and nonthreaded closures consume approximately 2 billion lb of plastic material per year. A lot of these closures become part of consumer packaging where on-the-shelf appeal is important. The following is a real-life story of a difficult compromise between low cost and customer appeal.

The lowest cost is not always ideal.

Packaging is the largest single market for plastic materials. Bottle caps represent a major market for U.S. molders. Threaded and nonthreaded closures consume approximately 2 billion lb of plastic material per year. A lot of these closures become part of consumer packaging where on-the-shelf appeal is important. The following is a real-life story of a difficult compromise between low cost and customer appeal.

|

Marketing managers never cease redesigning their packaging in an attempt to increase the product’s ability to attract customers. Cosmetic packaging is the epitome of this over-the-top package design. There are many instances in which these packages cost more than the product. One only has to walk the aisles of a drug, department, or grocery store to be impressed with what this trend has produced.

Packagers’ propensity for redesigning their closures has provided me with a lot of work. I can no longer recall how many threaded, snapfit, decorative, child-proof, dispensing, and tamper-evident closures I have worked with.

Over the years I have come to realize that closures are now so common they are taken for granted. Many consider closures as commodity products that can be sourced on price alone. This is a mistake, as most closures are sophisticated parts with many functions to perform. One primary function is the ability to be efficiently and reliably mass-produced to high quality standards. A few out-of-spec closures can shut down a high-speed bottle-filling line.

In years gone by, customers secured several quotes for molded closures. All other things being equal, the lowest bidder got the project. That may not have been the absolute lowest possible cost, but it was the price the customers paid. This was a good business model. It sold a lot of molds, plastic material, and molding machines. New companies appeared and prospered with the creation of many jobs.

Customers still buy from the lowest bidder, but only after negotiating a further reduction in cost. Many projects are only let after the molder also agrees to give the customer an annual cost reduction. As a result, molders have become more efficient, but profit margins have suffered, reinvestment capital is scarce, and much of the fun of doing business has been lost.

Extreme pressure to reduce cost

For the past few years, everyone in the injection molding industry, except for the material manufacturers, has been under extreme pressure to reduce cost. The real motivation is to increase profits. The lowest cost now seems to have priority over all other considerations. In many instances, function and quality suffer accordingly. Cost is important, but no more so than other factors.

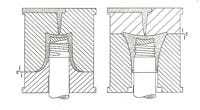

For example, the two core and cavity inserts shown above represent different approaches to molding a threaded closure for a cosmetic product. Both closures are equally capable of sealing a bottle for storage and shipping, or opening that bottle to dispense product. The closure on the left has a relatively thin wall and can be molded on a short cycle. The closure on the right has a thicker wall that uses more plastic material and requires a longer molding cycle.

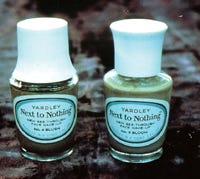

Those who worship at the altar of low cost would instinctively choose the left-hand closure. They would, however, be sorely disappointed once that product reaches the marketplace. The drawings don’t show it, but these two closures create very different images once they are assembled onto their bottles. That difference is obvious in the photograph.

Both labels and bottles are the same. All that is different is the closures. The closure that flares out at the bottom blends nicely with the shoulder of the bottle. That closure looks like it was designed for that bottle, but it makes the whole package look heavy. Regrettably, that combination of bottle, label, color, graphics, and closure does not sparkle. This package wouldn’t stand out amidst all of the other face makeup products on the shelf. There is nothing to attract the shopper’s attention.

The closure, bottle, and label on the right present a very different lighter and more feminine image. The shape and the proportions somehow create a more interesting and attention-getting appearance. The outward-flaring closure invites the shopper to pick up the product. The customer has now stopped walking and is concentrating on the product. This increases the possibility that the label on the back of the bottle that describes the benefits of the product will be seen and read. This increases the product’s chances of being purchased. This is an extremely important attribute of a package, as there is normally no salesperson present except in the cosmetic departments of high-end stores. With no one present to promote the product, a package’s ability to sell itself is actually more important than the lowest possible cost.

Cost and tooling considerations

The closure on the left, molded in a white polypropylene, could be produced for $8.43 per thousand less than the part on the right. This doesn’t seem like much, but it comes to more than $250,000 on estimated sales of 30 million units. Any cost-conscious buyer would prefer to purchase the lower-cost closure.

Prudent molders would also prefer the closure on the left, which is not only lower in cost but is also easier to mold with no concern for sink marks or voids in the thicker walls on the right-hand part.

This is a large-volume application. Mold maintenance is a concern. As the mold begins to show signs of wear, parting-line mismatch will be more of a problem for the closure on the right. Parting-line flash will be less of a concern for the closure on the left. In that case, flash will be at the shoulder on the bottle where it will not be noticeable and it normally will not be contacted by the user. Flash on the right-hand part will be located in a high-visibility area that the user’s hand will grip while opening and closing the bottle. Sharp flash in this area can be painful.

The closure on the left has a lower cost and a number of other desirable features. It does, however, lack the ability to attract the attention of the hurried customer walking the aisle and scanning the shelves. Going into production with the part on the left would be a serious mistake. That part will never be able to sell itself as well as the part on the right. Low cost and ease of manufacturing are important considerations, but they cease to be of concern if the product doesn’t sell. Regrettably, the cost of the mold and a lot of time will be lost before the package’s lack of customer appeal becomes obvious.

The first rule of part design is to maintain a uniform wall thickness. The right-hand closure violates that rule. Proper part design and the lowest part cost are important, but in this case, on-the-shelf customer appeal is more important. In the final analysis no design is successful unless the product sells.

Both of these closures were prototyped and a few thousand samples were molded. For obvious reasons, focus groups chose the right-hand closure and the product became a long-lasting financial success.

About the Author(s)

You May Also Like