DuPont: Biobased engineering plastics offering performance without compromise

There are probably a lot of people who don’t realize it, but DuPont (Wilmington, DE) currently offers the industry’s widest range of biobased, engineering grade polymers, with performance attributes that range from strong and stiff to flexible. DuPont’s biobased, engineering grade polymers have been used in a variety of applications, from vehicle components and residential carpets to sporting goods and cellphones. Many of the new products have earned innovation and sustainability awards.

December 9, 2015

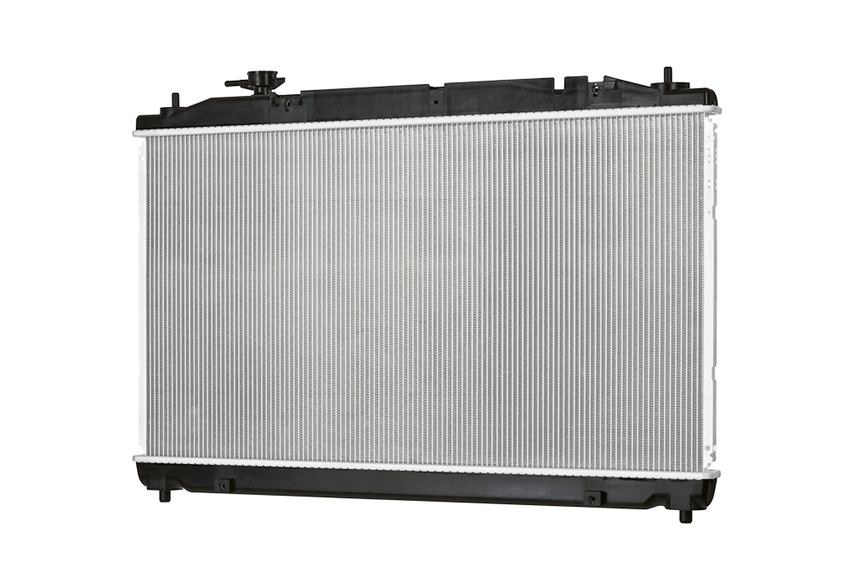

There are probably a lot of people who don’t realize it, but DuPont (Wilmington, DE) currently offers the industry’s widest range of biobased, engineering grade polymers, with performance attributes that range from strong and stiff to flexible. DuPont’s biobased, engineering grade polymers have been used in a variety of applications, from vehicle components and residential carpets to sporting goods and cellphones. Many of the new products have earned innovation and sustainability awards.  In fact, the Toyota Camry radiator end tank pictured won the Most Innovative Use of Plastics award in the Environment Category from the Society of Plastics Engineers (SPE) Automotive Division for Toyota and partners Denso and DuPont Automotive. It just happens to be made from renewably sourced DuPont Zytel RS nylon.

In fact, the Toyota Camry radiator end tank pictured won the Most Innovative Use of Plastics award in the Environment Category from the Society of Plastics Engineers (SPE) Automotive Division for Toyota and partners Denso and DuPont Automotive. It just happens to be made from renewably sourced DuPont Zytel RS nylon.

“Biopolymers have quietly infiltrated many markets based on the combination of environmental and performance benefits,” said Rick Bell, Development Manager for DuPont Performance Polymers. “That combination will continue to drive higher-value consumer products.

Both Rick Bell and his colleague Karlheinz Hausmann, Sustainability Technology Leader of DuPont Packaging & Industrial Polymers will talk about high-performance materials solutions in packaging, automotive and other consumer markets at this week’s European Biopolymer Summit 2015, organized by ACI in London.

“We want to familiarize people with the options and challenge them to think differently about how to get the greatest performance from the materials they have to work with,” Bell explained.

“We’re converting petro-based plastics ingredients to renewables where it's technically feasible and cost-effective and we’re developing entirely new polymers—with completely different performance characteristics—based on these bio-based ingredients,” he added.

However, for these materials to form an economically viable alternative to conventional fossil-based materials, at least two preconditions apply, said Bell.

“For us to bring the science to market, though, the materials must offer better performance and better cost position than the materials they would replace.”

At the summit, Bell will join sustainability and commercial leaders from Sabic (Riyadh, Saudi Arabia), Innovia Films (Cumbria, United Kingdom) and BioAmber (Montreal) to discuss new commercial developments and the business case for renewably sourced materials on Dec. 10, in the morning.

Karlheinz Hausmann also emphasized the need for biopolymers to perform at least as well as their petroleum-based equivalents or bring new, differentiated performance profiles.

“When you consider packaging from a holistic sustainability aspect, recycling and lightweighting are increasingly important and need to be compatible with the chosen biopolymer approach,” he said. “As in all industries, the brand owners need to recognize and support the value proposition of biopolymers in context with sustainability goals for respective applications.”

In London, Hausmann joins packaging and environmental experts from Nestle (Vevey, Switzerland) and consulting firm Smithers Pira (Leatherhead, Surrey, United Kingdom) to discuss brand and retailer perspectives on the growing role of bioplastics in products and packaging on the morning of December 9.

The two-day European Biopolymer Summit conference will address how the industry will evolve, current trends, how to respond to the changes of the market and the growing demand from end users. Key topics will include trend reports on bio-based building blocks and polymers in the world, the impact of declining oil prices on the biopolymer business, cutting-edge advancements in biopolymer production and many more.

About the Author(s)

You May Also Like