Low-emission acetal finds favor in steering column

Buffer-stops made of Delrin 100PE grade low-emission acetal resin from DuPont (Wilmington, DE) cushion the impact when mechanically adjustable steering columns from ThyssenKrupp Presta (Eschen, Liechtenstein) reach full horizontal adjustment.

May 15, 2012

Buffer-stops made of Delrin 100PE grade low-emission acetal resin from DuPont (Wilmington, DE) cushion the impact when mechanically adjustable steering columns from ThyssenKrupp Presta (Eschen, Liechtenstein) reach full horizontal adjustment.

Decisive factors in specification of this material were its compliance with stringent emission levels demanded by some of Germany's automotive OEMs for interior applications and its steel-like springiness. The material also is characterized by its vibration damping effect, its high notched impact strength and very good sliding properties.

|

Small spring element made from low-emission grade DuPont Delrin 100PE cushions impact in steering column. |

|

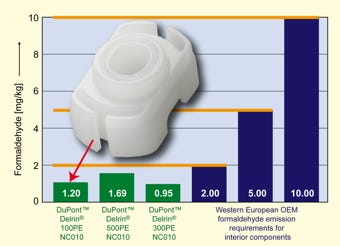

Testing in accordance with the VDA standard 275 confirms that all three low-emission grades of Delrin meet emission requirements of the world's major automotive manufacturers. |

The buffer-stop, injection-molded in Delrin 100PE, takes up very little installation space with its 14 mm x 9 mm x 6 mm dimensions. Held by a rivet, it slides during adjustment of the steering column on metal guide rails until they reach their limit at the end of the adjustment range. Although the associated jolt may in some cases be hard, two small springs on either side of the buffer-stop are enough - thanks to the high stiffness and elasticity of the material - to cushion the impact both mechanically and acoustically. Moreover, as a direct benefit of the excellent sliding properties of Delrin acetal resin, the buffer-stop will continue to move easily, softly and virtually inaudibly on the guide rails for the entire lifetime of the vehicle.

According to Ingo Weise, project manager at ThyssenKrupp Presta: "Acetal is an established material for damping elements used in steering columns. We have often used Delrin 100P for similar parts in earlier designs where it met our requirements. In this particular case, however, we needed to meet especially strict emission levels. We therefore worked with DuPont Performance Polymers on finding an alternative, including carrying out required testing. This ultimately resulted in us specifying Delrin 100PE."

Martin Elmer, marketing manager for injection molding at Huber+Suhner (Herisau, Switzerland) adds: "We produce these high-precision parts that are characterized by their variable wall thicknesses, in 16-cavity hot runner molds and keep within a tolerance of just ±0.05 mm. Because the processing requirements of the new, low-emission Delrin 100PE are almost identical to those of the 100P grade, we were able to adapt our production in the shortest of time and without compromising quality, all with the help of the experienced application technicians from DuPont."

Based on the direct and simple changeover in production, as well as the very positive experience to date during serial production, ThyssenKrupp Presta is planning to use Delrin 100PE for further automotive applications of a similar nature.

The combination of high elasticity and stiffness as well as excellent sliding properties are said to make Delrin acetal homopolymers a material of choice for applications requiring low weight and where elements are required to absorb high forces, levels of deformation and impact, as well as to continuously move both smoothly and quietly. According to Hans-Hermann Kirner, material development leader for vehicle interiors at DuPont, "Gears and adjustment mechanisms are ideal applications for Delrin. In view of the strict limits with regard to the emission of volatile particles, Delrin 100PE is a very suitable application located within the vehicle's interior." It is able to meet the demands of the global automotive industry with regard to emissions of volatile substances during both processing and use. The same applies to the higher flow grades Delrin 300PE und 500PE.

Tests conducted by SGS Institut Fresenius (Taunusstein, Germany), in accordance with VDA 275, revealed emissions of below 2 mg/kg for all three grades, whereas their strength, stiffness, impact resistance and resistance to creep and fatigue are the same as standard grades." DuPont has also recently introduced Delrin 127UVE, 327UVE and 527UVE, which are all UV-stabilized versions of its low-emission acetal resin for automotive interior applications.-[email protected]

About the Author(s)

You May Also Like