New company, new energy management system for plastics plants

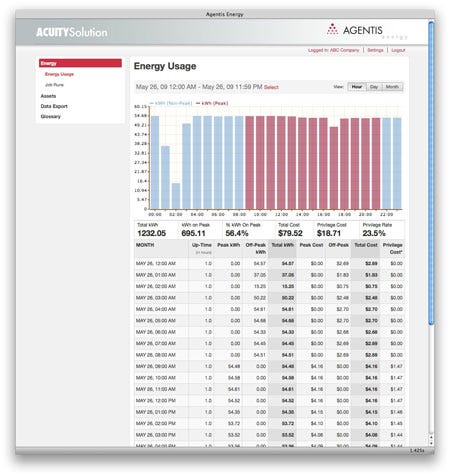

Agentis Energy (Elmhurst, IL), a brand-new company making its debut at NPE2009, will be showing a technology whose time, as we say, has come. The Acuity Solution, as it’s called, is a Web-based energy monitoring system that can track every electrical device in a processing shop and visualize the analysis in a simple form so adjustments can be made that start saving energy (and money) nearly instantly.

June 5, 2009

Agentis Energy (Elmhurst, IL), a brand-new company making its debut at NPE2009, will be showing a technology whose time, as we say, has come. The Acuity Solution, as it’s called, is a Web-based energy monitoring system that can track every electrical device in a processing shop and visualize the analysis in a simple form so adjustments can be made that start saving energy (and money) nearly instantly.

Agentis is an independent partner company of well-known temperature controls supplier Fast Heat and the two will share NPE Booth W122008. The Acuity System tracks kilowatt-hours in real time at the device or even job level, and calculates costs based on peak or off-peak consumption times. The company notes that many shops have been monitoring energy on a plantwide basis, but Acuity lets them see exactly where and how much energy is being used by a specific device.

|

Acuity will monitor everything and anything drawing power in the shop using sensors easily installed on the devices. The sensors are connected through an innovative new technology called mesh networking, and except for some short spans, the connections are wireless. The Agentis sensors, which are robust enough for military use, can pass data to the next sensor, which can pass it on relay-style until it reaches an intelligent router that sends it to the Acuity server.

CEO of Agentis Energy, Tim Stojka, also CEO of Fast Heat, notes that processors have been paying utility bills with little or no knowledge of the specific factors contributing to what is a really big expense. “Even more energy will be used in the future as demand grows,” he adds. So costs will grow as well.

Acuity sensors can be easily installed on any equipment in a production line or system. The data they collect travel via a secure connection and can be viewed in any Web browser using the software that Agentis director of business development John Lux terms a key ingredient of the system.

The company’s website, complete with a software demo, will be completed soon, but in the meantime, visit www.fastheat.com and click on “Energy Intelligence” or stop by the Agentis/Fast Heat NPE booth to find how to get a handle on energy costs before they become too big to handle. —[email protected]

About the Author(s)

You May Also Like