Nylon grade boasts strength and stiffness, with surface finish to boot

Challenging injection molded applications such as office chairs, outdoor power equipment, outboard motor covers, and gun stock components now can benefit from using a 17% glass-fiber-reinforced nylon 6 compound that is said to provide an optimum combination of strength and stiffness. Chemlon 217 GI from Chem Polymer, a unit of Teknor Apex Co. (Pawtucket, RI), is said to exhibit high levels of stiffness, flexural strength, and tensile strength.

December 8, 2009

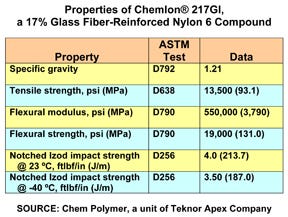

Challenging injection molded applications such as office chairs, outdoor power equipment, outboard motor covers, and gun stock components now can benefit from using a 17% glass-fiber-reinforced nylon 6 compound that is said to provide an optimum combination of strength and stiffness. Chemlon 217 GI from Chem Polymer, a unit of Teknor Apex Co. (Pawtucket, RI), is said to exhibit high levels of stiffness, flexural strength, and tensile strength. It also “provides the practical toughness that rugged-use applications require, while yielding an excellent surface even though it is a glass-filled formulation,” says Todd Bresson, national sales manager. “Its outstanding flow characteristics make it suitable for large parts.”

|

The compound is impact modified and UV stabilized, making it suitable for outdoor and low-temperature environments. Bresson notes that a customized formulation of the compound has been used commercially for the one-piece molded inner shells of office chairs, where exactly the right balance of flexibility and stiffness is needed to combine structural strength with user comfort. —[email protected]

About the Author(s)

You May Also Like