Radically repeatable screw tip

November 10, 2008

|

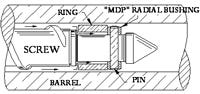

??A shaft and retaining bushing assembly designed to restrict the forward motion of the ring to determine stroke during plasticating is a key feature of a new patent-pending, sliding-ring nonreturn valve. The ring is forced against the assembly through viscous drag. Then the plastic’s hydraulic pressure transforms the sliding frictional force that usually occurs between the shaft and bushing into a radial force, resulting in very low pressure drop and consistent part weight, shot after shot.

“It is well known that a radial motion is less abrading than a sliding force, which contributes to less wear between these members,” says Mike Durina, president of Md Plastics Inc. (Columbiana, OH), developer of the new screw tip, called the MDP. “In addition, this geometry contributes to much lower pressure drop across the ring, which is the primary component in ensuring shutoff accuracy and shot-to-shot consistency.”

Following initial tests at Md Plastics, at an independent research lab, and at a major supplier of front-end components, subsequent testing reportedly has proven the MDP to be 10 times more accurate than more conventional screw tips. Durina also says that field tests measuring cushion performed at a leading parts manufacturer in the U.S. Midwest proved that the Cpk value using the MDP was 4.21 vs. a 1.01 Cpk when using more conventional three- or four-piece industry-standard screw tips.

Durina adds that more precise screw tips allow you to mold parts more precisely and often at a lower pressure, which can reduce part weight. “Most molders default to overpacking the compressible plastic fluid, rather than experiencing a short shot, but this leads to a ‘heavy’ molded part, and heavy parts lead to lost revenue when running costly materials.”

Md Plastics’ MDP nonreturn valves are competitively priced and can be supplied in optional materials of construction to extend their service life, even in the harshest environments.

Readers may recall Durina’s involvement in the introduction of the Posi-Melt general-purpose screw, designed to provide superior melting capabilities, more homogeneous mixing, and the ability to deliver a cooler melt (see imm.plasticstoday.com/?q=articles/10930).

?Md Plastics Inc.

www.mdplastics.com

About the Author(s)

You May Also Like