Study shows the environmental benefit of EPS

Recent efforts in California, Chicago and New York to ban EPS products such as packing peanuts and foodservice items are being challenged by environmentalists and industry experts who argue that the bans will do more harm than good.

October 1, 2014

Recent efforts in California, Chicago and New York to ban EPS products such as packing peanuts and foodservice items are being challenged by environmentalists and industry experts who argue that the bans will do more harm than good.

While EPS foam was once thought to be environmentally unfriendly, the new study "Impact of Plastics Packaging on Life Cycle Energy Consumption & Greenhouse Gas Emissions in the US & Canada Substitution Analysis" proves otherwise. Data from the report, which was compiled by Franklin Associates for the American Chemistry Council (ACC) and the Canadian Plastics Industry Association, shows that replacing plastic packaging with alternative materials would result in 4.5 times more packaging weight based on figures from 2010, as well as an 80% increase in energy use and 130% more global warming potential.*

The study shows the unintended results of bans on plastic packaging. Glass alternatives come with higher environmental costs in terms of manufacturing, transportation and even recycling.

Along with the environmental benefit, EPS foam is the best shipping material for shock absorption and thermal protection. Insulated EPS wine shipping containers protect fine wines from breakage and temperature fluctuations during transit. Because of EPS shipping containers, mail order steaks stay frozen to perfection and temperature-sensitive and fragile pharmaceuticals remain viable.

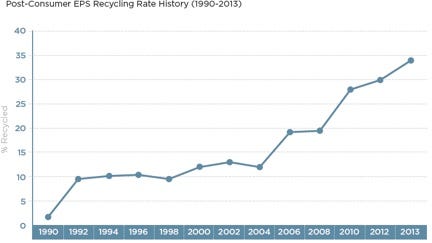

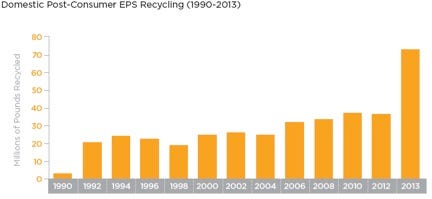

The same EPS foam that protects wines, meats, and pharmaceuticals can be commercially recycled. EPS recycling has increased year in and year out. Due to innovative outreach programs, in 2013, total domestic EPS recycling grew to 127.3 million pounds, with 72.8 million pounds of post-consumer material and 54.5 million pounds of post-industrial, according to a study from the EPS Industry Alliance.** The 2013 recycling rate is up 35% over 2012 in which 93.7 million pounds of both post-consumer and post-industrial EPS was recycled.

Corporations like Chick-Fil-A, Walmart, and Best Buy have launched EPS recycling initiatives that have been hugely successful-reducing each of the corporations' environmental footprint and providing feedstock to manufacturers of recycled content products.

Of EPS foam cups, the Chick-Fil-A website says: "We continually receive positive customer feedback on the insulating properties of our cups. Through research and tests of a number of 'environmentally-friendly' cup options, we have concluded that none serve our customers as well as the foam cup." Surprisingly, most paper based cups use a glue that prevents them from being recycled. Chick-Fil-A is among one of the first restaurant chains in the country to successfully implement a large-scale foam recycling program. With the help of Dart Container, Chick-Fil-A is now recycling foam cups at 25% of its 1700 locations, and plans on reaching the 100% mark by 2015.

There is a high demand for recycled EPS, which can be used in frames, hangers, interior moldings, surfboards, and other products. Recycled EPS costs less than wood. Right now, the supply of recycled foam is not keeping up with demand-an incentive for would-be recycling entrepreneurs.

* Franklin Associates, A Division of Eastern Research Group. "Impact of Plastics Packaging On Life Cycle Energy Consumption & Greenhouse Gas Emissions in the United States and Canada". January, 2014. http://plastics.americanchemistry.com/Education-Resources/Publications/Impact-of-Plastics-Packaging.pdf

** 2013 EPS Recycling Rate Report, http://www.epsindustry.org/sites/default/files/EPS%20Recycling%20brochure%208.5x11.pdf

Mary Burk is a marketing specialist at ACH Foam Technologies. Editor's note: The author is a PlasticsToday contributor. The opinions expressed are those of the writer.

About the Author(s)

You May Also Like