The Troubleshooter, Part 123: Everything was just about perfect

A PC part encounters a common defect.What a great morning! The sun had been up for a couple of hours, the birds were happy as could be, and the squirrels were running up and down the backyard fence. Then it happened: Two air-freight delivery trucks pulled into the drive at pretty much the same time—the first double delivery I remember in a long time.

May 5, 2010

A PC part encounters a common defect.

What a great morning! The sun had been up for a couple of hours, the birds were happy as could be, and the squirrels were running up and down the backyard fence. Then it happened: Two air-freight delivery trucks pulled into the drive at pretty much the same time—the first double delivery I remember in a long time.

|

I took a look at the contents of the boxes being delivered and figured out right away I had a story that needed telling. Surprisingly, it wasn’t because the parts in one of the boxes were so bad, but because they were almost perfect.

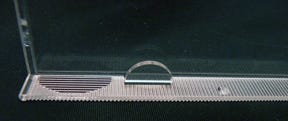

They were fairly rigid and quite clear, and looked like security packaging for compact disks or DVDs. For once, I found a note in the box, which focused on the molder’s customer complaints.

The complaints centered on breakage of the four 3/8-inch-diameter half-circle ears attached to the case’s front cover. These little ears hold the literature against the front half of the part for display purposes. The material was polycarbonate; the molder was using a hot runner gate that measured 0.060 inch in diameter. The walls were 0.065 inch thick and the part appeared to be well molded.

Watch the radius

Except for the ears breaking off, I couldn’t see a thing that needed to be changed. I looked for missing radius, such as where horizontal and vertical walls join, but at first glance, all bases seemed to be covered. However, when I methodically scanned around the outside edge of the part, I could see several places that lacked critical radiuses.

The cavities that produced the back side of the parts seemed to be well radiused, but the cavities that produced the front side were missing radiuses in quite a few places. It would be a simple procedure to put radiuses where they belonged, but the important part of this fix would be to explain to the molder, the tooling engineer, and the toolmakers why the lack of radiuses on this part was such a big deal: Polycarbonate is very notch sensitive, and the impact values of PC parts containing sharp corners or edges suffer greatly.

I use a “critical thickness” chart in my best seminar presentation that lists the maximum wall thickness achievable in any given melt flow grade of PC before the impact value of the material drops by 90%. Can you imagine designing a part like this one to use an easy-flow PC grade and then finding out that the impact value of the material turns out to be 1.4 ft-lb instead of the 14 ft-lb indicated on the material data sheet? There are critical wall thicknesses that should not be exceeded for all melt flow grades of PC, even the stiffer-flow grades that are considered to have the highest impact values of all the polycarbonates.

|

Another issue with polycarbonate is its poor chemical resistance. Here was a part being used to display CDs or DVDs in the stores and at home, and if someone cleaned these packages with a strong cleaner, they would be liable to ruin the clarity of the part and destroy its function.

But the most important rule to remember when molding polycarbonate is that easy-flow polycarbonate has a tendency to crack, so try not to use grades with melt flow numbers in excess of 16 without a darn good reason.

I went through both sides of this packaging design and listed six notch-sensitive areas that the toolmakers needed to check. The back side of the package was not as vulnerable as the front half since the back half was composed of two parts sandwiched together. This did two things for them: 1) it made the back half of the part stiffer, and 2) it did not allow access to the several notch-sensitive areas by outside forces. The front half of the part was only a single-wall design and did not have this extra protection, so generous radiuses were the only answer.

PC ignorance

This was one of those hard-to-figure-out parts where it appeared that more than one designer or moldmaker worked on the mold concurrently, probably to speed up the project.

I called the molder and discussed the corrective actions with the toolroom supervisor at length. His only comment was one I hear all the time: Why is it so hard to find out these things about the materials we’re planning to run? I suggested he or someone in their company contact the PC manufacturer to see if it would furnish them with design information that toolmakers would find helpful when designing and building molds to produce PC parts.

I thought I was finished with this project when I got a call from the molder. He was following up on the information I passed on to the toolroom supervisor. He went through each point with me and asked if I could schedule some time in the near future to visit his molding shop and present a seminar for his key people, which, of course, I was willing to do.

Sometimes it’s hard for me to believe that a material like polycarbonate has been around for 50 years and so many people know so little about it. I’m not complaining, though; it’s the little-known facts like these that keep me busy.

Troubleshooter’s notebook

Part/material: Polycarbonate CD/DVD case.

Tool: Hot runner

Symptoms/problem: Tabs for holding literature in the front case were breaking.

Solution: Radius the corners on the tabs for the front cover.

About the Author(s)

You May Also Like