Purchasing Basics: Resin dryers

May 23, 2001

Improper drying of materials is the root cause of many types of cosmetic defects. Does every material need to be dried? No. Can most plastics materials benefit from a trip through a desiccant bed dryer? Absolutely. But if you are molding nylon, PET, polysulfone, or cellulosics, adequate drying temperature and thorough drying are a necessity. Also, the clearer the material, the more likely cosmetic defects caused by underdrying will show up.

Not all resins are hygroscopic, meaning that the pellet itself absorbs moisture from the ambient air. But they may still attract moisture that stays on the surface. In such materials as polyethylene or polypropylene, this surface moisture is easier to remove, but it still requires drying. So let's start with the basics.

Resin Influence

The type of resin you are drying is the foundation of what drives the selection of a dryer. The chart below lists many of the individual resins that benefit from drying, along with recommended drying temperature and drying time, compiled from a variety of sources and cross checked against the resin suppliers' recommendations.

|

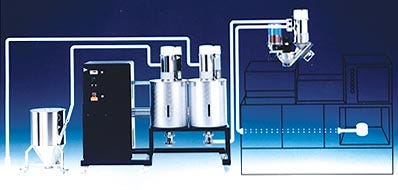

Dryers can be machine mounted, beside-the-press, central, or portable. They can dry one or many hoppers. |

But there's more to it than just resin type. What shape or size are your pellets? Large pellets don't get as dry as small pellets at the same exposure. When drying ABS, for example, 5 hours of drying will take a batch of small pellets down to .025 percent residual moisture, while the same period and temperature will take large pellets down to only .075 percent.

Rules of Thumb |

|

The chart also shows a nominal starting moisture level and the desired residual moisture level at molding. The greater the difference in these two numbers, the more residence time is required in the hopper, thus the size of the hopper (and its location) are affected.

What about additives that might be present in your material—volatiles that might be released on drying? If such volatiles are released, they may damage the desiccant. So they must be trapped before they enter the desiccant carousel. Your dryer supplier will want to identify these.

How clean is your resin? Is it all virgin material, or is there regrind, with its attendant dust that can foul the desiccant bed of the dryer? This will determine the degree to which the air will be filtered for contaminants; with a high level of dust or fines, a stand-alone return air dust collector may be required.

Process Considerations

How much resin will you need to dry in what period of time? Dryers come in two parts, basically: the dryer, where desiccant is used to create low-moisture air, and the hopper, which contains the resin to be dried in a configuration that allows the dry air produced by the dryer to pass over the moist resin to remove moisture.

First, will you need a dryer that mounts on a molding machine? Sits next to a molding machine? Or performs a higher-volume drying function in a central location, feeding multiple molding machines?

If it's to be at the machine, what model of molding machine do you have? What's the cycle time of the product? Where should the hopper be placed—on the machine or on the floor? Is there adequate floor space or ceiling height to accommodate the equipment at its preferred location? Is there adequate air pressure available at the machine? Is compressed air available?

Your dryer supplier will need a drawing of the flange on the barrel of the molding machine where the hopper is attached, and will want to know how high that flange is off the floor and what the ceiling limit is over that machine.

Recommendations for resin drying | ||||||||||||||||||||||||||||||||||||||

|

What's your preferred power source? Gas-fired dryers have become popular because of their much lower energy consumption per pound of resin dried. The more often the desiccant bed needs regeneration, the higher the power consumption. Different dryer designs require different power consumption, and it's wise to evaluate potential suppliers on energy consumption data.

If you are in an area of high energy costs, special dryer features, such as a power regulator, may be available. Ask your dryer supplier if he will provide an energy audit of your situation to help you evaluate your conservation options.

What's the ambient air like in your plant on a year-round basis? What are temperature extremes in the plant and variation in relative humidity from summer to winter? Drying efficiency is not independent of the weather outside. Prepare yourself to answer these questions, and you'll be off to a good start in your purchasing plans.

With our thanks . . .

. . . to the drying experts at Comet Automation, Conair, Fasti, and Novatec for supplying material for this article.

Go to the IMM Almanac Online home page.

You May Also Like