StackTeck’s IMC technology reaches more than 1,000 cavities

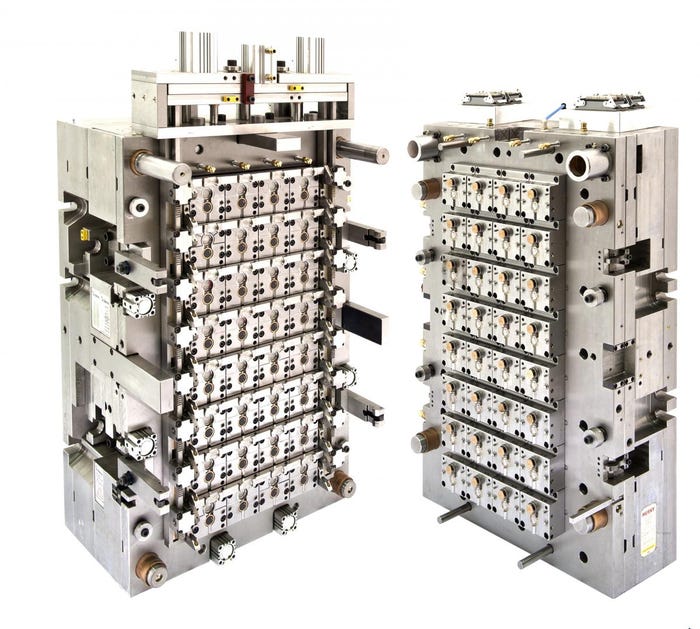

StackTeck Systems Ltd., known for its innovations in mold technology to provide solutions to OEMs in the consumer and packaging markets, announced an important milestone reached in the production of In-Mold Closing (IMC) mold: StackTeck has designed and built molds totaling more than 1,000 IMC cavities. StackTeck currently has these IMC systems running in manufacturing plants around the world.

February 5, 2015

StackTeck Systems Ltd., known for its innovations in mold technology to provide solutions to OEMs in the consumer and packaging markets, announced an important milestone reached in the production of In-Mold Closing (IMC) mold: StackTeck has designed and built molds totaling more than 1,000 IMC cavities. StackTeck currently has these IMC systems running in manufacturing plants around the world.

In the last two years, more than 90% of the flip-top molds have been ordered with IMC capability to take advantage of the technology's precision of the closing motion. The opportunity to close the living hinge on a cap/closure while the plastic is still hot provides a better quality part and an improved life of the hinge. The closing device capability has been enhanced to provide precise guidance for special flip-top applications with narrow hinges or unusual part shapes.

While IMC for caps and closures has been utilized for several years, StackTeck has taken the technology a step further for a broader range of applications. For example, StackTeck developed IMC for disposable cutlery with folding handles that lock into place for use. The advantages of the folding cutlery include the reduction of the size of the cutlery that accommodates smaller packaging.

While IMC for caps and closures has been utilized for several years, StackTeck has taken the technology a step further for a broader range of applications. For example, StackTeck developed IMC for disposable cutlery with folding handles that lock into place for use. The advantages of the folding cutlery include the reduction of the size of the cutlery that accommodates smaller packaging.

Development of the IMC technology also includes the incorporation of multiple, separate motions of the closing arms while optimizing the control of the closing force, particularly for high-cavitation molds. It also allows more motions within the mold to accommodate various parts with more complex geometry. Evolutionary designs have also enabled StackTeck to reduce the footprint of the mold design of the closing arms, making it more compact and allowing a higher cavitation in any given press size. This also minimizes the stroke distance required for closing, and maintaining the fastest possible cycle times to ensure not only high quality but reduced cost to manufacture.

"StackTeck's reputation for innovation and creativity in not only solving customers' current challenges but anticipating our customers' next-generation of product requirements makes StackTeck a global leader in high-production, high complexity molds that leading OEMs rely on to deliver big mold programs," said Henry Rozema, VP of sales and marketing for StackTeck Systems Ltd.

StackTeck's extensive services and capabilities include in-house mold qualification, process validation and full system integration (robotics and automation), with the ability to perform total system evaluations in house using state-of-the-art injection molding machines. The company also offers in-house training of its customers in the set-up, operation and maintenance of these complex molding systems.

Several StackTeck systems will be running in partnership with several molding machinery companies at NPE2015. Watch PlasticsToday for more information about these exciting demonstrations.

About the Author(s)

You May Also Like