New composite with good mechanical strength and high electrical conductivity

August 2, 2016

The Institute of Plastics Processing (IKV) in Industry and the Skilled Crafts at RWTH Aachen University is carrying out research into a new approach for the production of graphite-filled polypropylene compounds. IKV is collaborating closely with six other partners on a project aimed at improving the mechanical properties of the compound compared with commercially available materials, while maintaining the same electrical conductivity.

The Institute of Plastics Processing (IKV) in Industry and the Skilled Crafts at RWTH Aachen University is carrying out research into a new approach for the production of graphite-filled polypropylene compounds. IKV is collaborating closely with six other partners on a project aimed at improving the mechanical properties of the compound compared with commercially available materials, while maintaining the same electrical conductivity.

To that end, a blend of polypropylene and elastomer was first produced to increase the elasticity of the matrix material. A mixture of selected, electrically conductive graphitic fillers was then incorporated. Efforts were made to keep the filler content as low as possible while still ensuring the necessary electrical conductivity for the specificr application – in this case, bipolar plates for fuel cells.

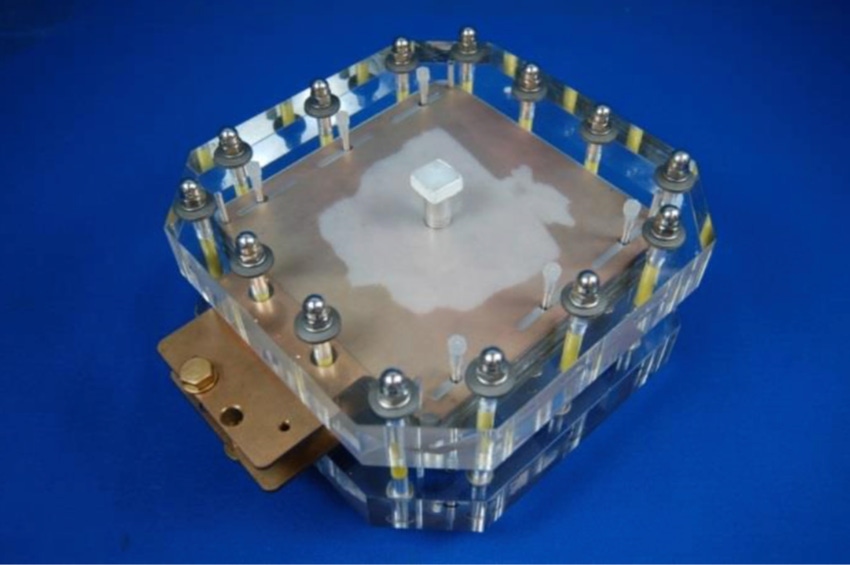

The project, which has received two years of funding from the German Federal Ministry of Education and Research (BMBF) is aimed developing a process allowing the conductive part of the bipolar plate to be compression molded from the highly filled compounds, then overmolded by injection molding, and finally joined to form a composite part. It is important here that the bipolar plates are welded to one other securely enough to ensure that they are gas-tight, and also that process reliability and high efficiency are ensured. The necessary joining technology is being systematically developed together with the various project partners at IKV. The composite material is now being tested in the fuel cell under conditions likely to be encountered in practice.

The newly developed, highly filled thermoplastic compound has considerable advantages over the currently used materials because of its reduced brittleness. A higher service life in the fuel cell and lower reject rates can also be achieved.

The other partners involved are Allod Werkstoff, Calorplast Wärmetechnik, Eisenhuth, Kessen Maschinenbau, Leibniz Institute for Polymer Research in Dresden, and Protech, all in Germany.

About the Author(s)

You May Also Like