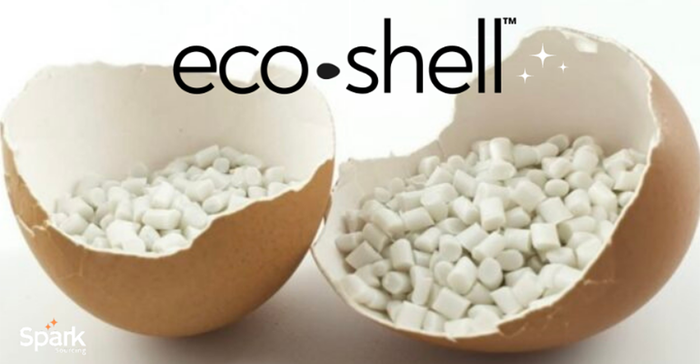

Eggshell-Based Filler Reduces Plastic Use

A bio-calcium plastic filler called “eco-shell” can reduce plastic use up to 50% — and products made from those compounds remain recyclable.

Taiwan-based Spark Sourcing is contributing to a circular economy for plastics with a sustainable, patented bio-calcium plastics filler that helps reduce the use of plastics and drives down carbon emissions.

Called eco-shell, the material is derived from eggshells. It can replace plastic content by up to 50% during plastics compounding. In addition, resins made with the filler are recyclable.

The eco-shell filler is compatible with numerous plastics, including polyethylene (PE), high-density PE (HDPE), low-density PE (LDPE), linear low-density PE (LLDPE), polyethylene terephthalate (PET), polypropylene (PP), ethylene vinyl acetate (EVA), polystyrene (PS), acrylonitrile butadiene styrene (ABS), ABS polycarbonate (ABS/PC), rubber, polyvinyl chloride (PVC), polymethyl methacrylate (PMMA), and polylactic acid (PLA).

Eco-shell can also be used with virgin plastic and in formulations containing recycled plastic, ocean-bound plastics, and bioplastics. Additionally, it reduces carbon emissions by 70% compared with virgin plastics processing.

Applications for plastics made with eco-shell include bottles and jars for pharmaceuticals, cosmetics, and cannabis products; consumer goods such as tableware, food storage bags, shopping bags, and electronics; foam mats and gym flooring; and industrial packaging, trays, pallets, buckets, and bins.

The filler’s anti-bacterial property is attractive for some of the applications, such as yoga mats.

Eco-shell patents and sustainability certifications.

In March 2023, the company that developed the filler, Taiwan-based Listen Green Technology, was granted a US Patent for the material (which it calls GEX) and for the material’s seven-step manufacturing method.

Listen Green also holds patents for the material in Australia, China, Taiwan, and the United Kingdom. Spark Sourcing, a Listen Green distributor, trademarked the material as eco-shell for its distribution territory.

“We work alongside [Listen Green] and act as their distributor for eco-shell, but also more intimately as their consultant for expanding to the West,” Andrew Bliss, founder of Spark Sourcing, tell us. “Their product is doing very well in Asia, but they wanted some guidance for expansion. They have several distributors, but we are more ‘in-house’ than the others.”

Sustainability certifications for eco-shell include Société Générale de Surveillance (SGS) eco-certification for plastic, waste, and reduction and the European Union’s Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) and Restriction of Hazardous Substances (RoHS) certifications.

In addition, eco-shell was recently certified recyclable under Europe’s EN 13430 standard for material recyclability in the post-use phase.

To learn more about this innovation and its advantages in the context of sustainability and beyond, we asked Bliss a few questions.

What’s the most common question potential customers ask, and what’s the answer?

Bliss: There are a few:

Many manufacturers are worried that our eco-shell will act just like CaCO3 — calcium carbonate, or limestone compounds — which can be rough on their machines. Eco-shell has much smaller and softer particles, however, and will not damage the machines at all.

Many also ask if products made with eco-shell are themselves recyclable, which we can now answer with certification that yes, they are.

We also get lots of questions about the manufacturing methods for which eco-shell is suitable. Injection molding, blow molding, calendering, and thermoforming are all okay.

Another important question we get is about our approach to sustainability and any advantages the material has over, for example bioplastics. Eco-shell is more focused on creating a circular economy for plastics, reducing as much as possible while making sure the end of life of the product involves recycling.

With eco-shell, clients can mix it with virgin plastic for a quick 25% plastic reduction. They can also create a very eco-friendly product by manufacturing with eco-shell plus recycled or ocean-bound plastic, for an even larger carbon reduction

In theory, a lot of bioplastics and additives that degrade plastics more quickly sound great, but the reality is different.

In addition to using a lot of energy in production and being very expensive, bioplastics are not recyclable and are difficult for consumers to separate and then compost at home. Most end up in the landfill, where they will not biodegrade, as the landfill does not have the soil requirements for doing so.

Also, once you add agents to petroleum-based plastics to increase degradability, the products cannot be recycled, meaning the end of life is usually a landfill.

For those products that use additives to claim biodegradability and have the required certificates, many will only achieve 10% biodegradability after 45 to 90 days. If this product — degradable but not digested by microorganisms — is then sent to a composting facility, it can cause problems because the products are not fast-composting and are not guaranteed to biodegrade in those conditions.

In what form is eco-shell supplied to plastics manufacturers?

Bliss: The fine white powder is pelletized before it’s shipped to manufacturers to mix into their compounds. We can also provide complete, ready-to-use compounds, for example, 30% eco-shell plus 70% recycled PP.

Are any equipment changes needed for plastics processors to use eco-shell?

Bliss: No equipment changes necessary at all. The eco-shell pellets will have to be dried out first, but that is the only step involved.

Is eco-shell available in North America?

Bliss: Yes, it is available! We have a Spark Sourcing office in Canada that that’s female-owned and in the Indigenous Business Directory due to

Native American manager Nicole Hollins.

From there, we are supplying manufacturers, working directly with brands, as well as bidding on government procurement.

Our Canadian arm is also developing a own list of products that we will manufacture and brand ourselves, including biodegradable cutlery and straws, office supplies, and even an eco-friendly and antibacterial yoga mat.

We also have US reps focused on specific industries. We are making strong strides into the cannabis packaging industry now, and we are working with other factories to develop new compounds based on our eco-shell.

Are there any downsides for plastics processors to use eco-shell?

Bliss: One of our greatest advantages is how seamlessly it can be incorporated. That said, we sometimes need to tweak the recipe to perfect a final product and its functionality. We generally send enough of the product so we can work together with the manufacturer to achieve this quickly.

About the Author(s)

You May Also Like