Mitsui Chemicals developing bio-PP production technology

The company is introducing its bio-Polypropylene Project at the G20 Ministerial Meeting in Karuizawa, Japan.

June 13, 2019

Mitsui Chemicals, Inc. has introduced its concept for a bio-polypropylene development project at the G20 Ministerial Meeting in Karuizawa, Japan. An exhibition showcasing state-of-the-art Japanese energy and environmental technologies under the theme of hydrogen energy, countermeasures for marine plastic litter and innovation is being held over June 14–16, 2019, at the Karuizawa Prince Shopping Plaza Carpark in Nagano Prefecture.

|

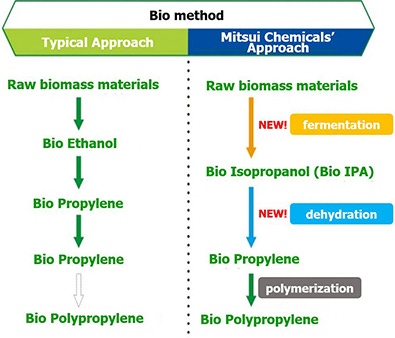

Mitsui Chemicals’ proposed route to bio-PP proceeds via isopropanol. |

The G20 Ministerial Meeting on Energy Transitions and Global Environment for Sustainable Growth is one of the ministerial meetings held in relation to Japan's presidency of the G20 Summit in Osaka in June 2019.

While widely used in a range of applications, spanning automobile-parts to medical care products, home appliances, housing and food packaging products, production of polypropylene from biomass has yet to be established at the industrial level.

Mitsui Chemicals’ proposal for a new production method for commercialization of bio-PP involves the fermentation of various biomass, mainly non-edible plants, to produce isopropanol (IPA), which is then dehydrated to obtain propylene monomer. Compared to other biomass production approaches studied by other companies thus far, this one could prove to be a more cost-effective way to manufacture bio-PP according to Mitsui Chemicals.

Others working on routes to polymerize bio-PP include Neste and IKEA, who aim to produce PP and polyethylene (PE) from renewable or recycled waste and residue raw materials, such as used cooking oil, as well as sustainably produced vegetable oils.

About the Author(s)

You May Also Like