New Bodies of Work in 3D Printing

3D printing is taking the manual labor and guesswork out of reconstructive and implantable device design while improving patient comfort.

April 4, 2024

Artificial ears and prosthetic implants are two of the latest anatomical achievements enabled by 3D printing.

Researchers at Weill Cornell Medicine and Cornell Engineering have assembled a replica of an adult human ear that looks and feels natural through a combination of tissue engineering and 3D printing. Conventional ear reconstruction requires multiple surgeries along with manual artistry and finesse, said Dr. Jason Spector, chief of the Division of Plastic and Reconstructive Surgery at Weill Cornell Medicine and NewYork-Presbyterian/Weill Cornell Medical Center and a professor at Weill Cornell Medicine. Although the resulting graft typically resembles the recipient’s other ear, it generally lacks flexibility, he added.

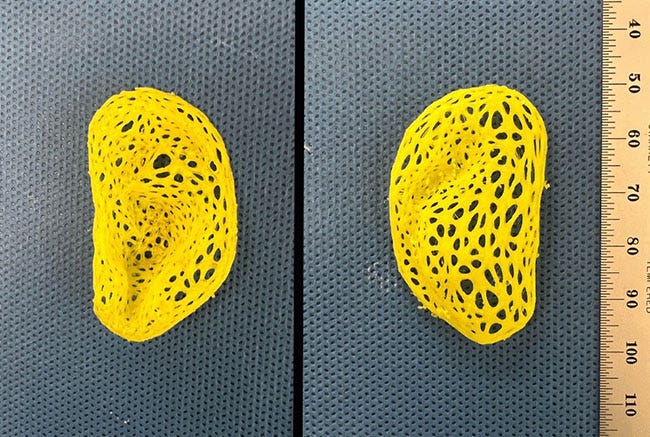

Plastic scaffold replicates patient’s ear

The technique developed by the researchers involves loading animal-derived cartilage into ear-shaped plastic scaffolds that have been printed based on data from the recipient’s other ear. The structure develops into cartilage containing tissue that replicates the ear’s anatomical features with an elasticity similar to human ear cartilage.

The plastic scaffold shown here was created on a 3D printer based on data from a person’s ear. Image courtesy of Spector Lab.

One remaining challenge for the researchers is making the engineered material as strong as natural cartilage so that it won’t easily tear. Spector believes incorporating chondrocytes — cells that build cartilage — would make the artificial ear more biomechanically similar to the native ear. That is now the focus of the research.

A study has been published in Acta Biomaterials.

On-demand implantable sockets

Researchers at Loughborough University in the UK have applied 3D printing to a different body part — lower-limb prosthetic sockets. They claim that their technique one day could allow the implants to be printed in remote locations and even in patients' homes.

Sockets typically are produced via a casting and molding process, and their manufacture relies on labor-intensive skills and trial and error, explains Dr. Simon Li, senior lecturer in mechanics of biomaterials, in the video below. A custom printing process and printing codes developed in house reportedly allow the researchers to optimize the load-bearing design of the socket for each patient and reduce printing times from as much as 50 hours to eight hours.

Moreover, the socket can be printed with a combination of hard and soft regions to improve patient comfort, said Li.

About the Author(s)

You May Also Like