Stratasys demonstrates next-gen 3D-printing technology at IMTS

August 30, 2016

Additive manufacturing pioneer Stratasys Ltd. (Eden Prairie, MN) will present a preview of the next generation of manufacturing technologies at the forthcoming International Manufacturing Technology Show (IMTS). As part of its "Shaping What’s Next" vision, Stratasys will showcase how its industrial-scale fused deposition modeling expertise responds to customers’ most challenging applications, from the rapid production of strong parts in sizes ranging from an automobile armrest to an entire aircraft interior panel. The ecosystem of additive and traditional technologies, software workflows, materials development and professional services align with individual manufacturing to revolutionize how parts are designed and built, said Stratasys.

Stratasys will feature the Infinite-Build 3D Demonstrator, designed to address the requirements of aerospace and other industries for large, lightweight thermoplastic parts with repeatable mechanical properties, at booth N-60 at IMTS, which runs from September 12 to 17 at McCormick Place in Chicago. The system turns the traditional 3D printer concept on its side to realize an “infinite build” approach, which prints on a vertical plane for practically unlimited part size in the build direction, explained Stratasys.

Stratasys will feature the Infinite-Build 3D Demonstrator, designed to address the requirements of aerospace and other industries for large, lightweight thermoplastic parts with repeatable mechanical properties, at booth N-60 at IMTS, which runs from September 12 to 17 at McCormick Place in Chicago. The system turns the traditional 3D printer concept on its side to realize an “infinite build” approach, which prints on a vertical plane for practically unlimited part size in the build direction, explained Stratasys.

Aerospace giant Boeing played an influential role in defining the requirements and specifications for the system, and is currently using an Infinite-Build 3D Demonstrator to explore the production of low-volume, lightweight parts. Ford Motor Co. is also evaluating the technology: In collaboration with Stratasys, it is testing new applications for automotive-grade 3D-printed materials that were not previously possible because of size limitations.

“Additive manufacturing represents a great opportunity for Boeing and our customers, so we made a strategic decision more than a decade ago to work closely with Stratasys on this technology,” said Darryl Davis, President, Boeing Phantom Works. “We are always looking for ways to reduce the cost and weight of aircraft structures, or reduce the time it takes to prototype and test new tools and products so we can provide them to customers in a more affordable and rapid manner. The Stratasys Infinite-Build 3D Demonstrator enables products to be made at potentially unlimited length, offering us a breakthrough tool to add to our robust additive manufacturing processes.”

Mike Whitens, Director, Vehicle Enterprise Sciences for Ford Motor Co., said, “3D printing holds the promise of changing automotive design and manufacturing because it opens up new ways to innovate and create efficiencies in production Our vision at Ford is to make high-speed, high-quality printing of automotive-grade parts a reality. We are excited about the future opportunities that the scalable and versatile Infinite-Build concept can unlock, and look forward to collaborating with Stratasys to help achieve our goals.”

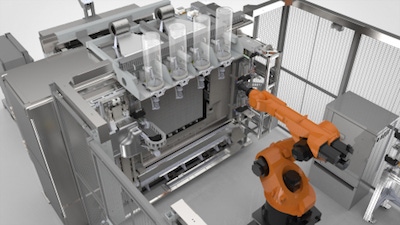

The 3D Demonstrator was made possible by a collaborative effort between Stratasys and Siemens to make 3D printing a viable and indispensable component of production manufacturing. As an example of this vision, Stratasys developed the Robotic Composite 3D Demonstrator integrating its core additive manufacturing technologies with industrial motion control hardware and design-to-3D-printing software capabilities provided by Siemens.

The goal is to reduce the labor-intensive processes and geometric limitations of traditional composite parts. The Robotic Composite 3D Demonstrator delivers true 3D printing using an eight-axis motion system that enables precise, directional material placement for strength while dramatically reducing the need for speed-hindering support strategies, explained Stratasys. This redefines how future lightweight parts will be built, and provides a glimpse into how this technology could be used to accelerate the production of parts made from a variety of materials.

“Siemens is pleased to support Stratasys in its innovative additive manufacturing initiatives, of which the Stratasys Robotic Composite 3D Demonstrator is one of the most promising,” said Arun Jain, VP, Motion Control, Digital Factory US, Siemens. “By working closely with Stratasys on motion control and CNC automation, Siemens is helping to create a flexible, multi-function manufacturing workflow that puts 3D printing firmly in the factory. We look forward to continuing to work with Stratasys to build manufacturing solutions that transform industries.”

About the Author(s)

You May Also Like