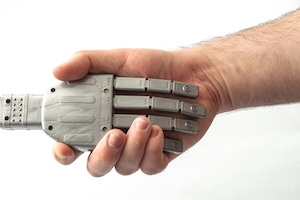

Collaborative robotics: The worker’s friend or foe?

The North American automation market set new records through the first nine months of 2017, and the market for collaborative robots is forecast to grow more than 50% through 2023. What this means for the human labor force is among the topics that will be addressed at PLASTEC West in February.

December 28, 2017

Will robots replace us? That is one of the key topics that will be debated at the forthcoming co-located Medical Design & Manufacturing (MD&M) and PLASTEC West event in Anaheim, CA.

Will robots replace us? That is one of the key topics that will be debated at the forthcoming co-located Medical Design & Manufacturing (MD&M) and PLASTEC West event in Anaheim, CA.

Employees in the manufacturing space understandably are worried about losing their jobs, especially with the advent of low-cost, nimble collaborative robots, or cobots. The fact of the matter is that humans probably will have a job, but chances are that they will be working increasingly alongside robots in the very near future. The economics of automation coupled with the rapid pace of technological change almost guarantee that evolution. PlasticsToday spoke with Melonee Wise, CEO of Fetch Robotics, who will take part in a panel discussion on robotics in Anaheim next month. But first, some context on the automation industry: Let’s do the numbers.

Recent figures released from the Association for Advancing Automation show that the North American automation market set new records through the first nine months of 2017 in the areas of robotics, machine vision, motion control and motor technology.

For the first nine months of 2017, 27,294 orders of robots valued at approximately $1.473 billion were sold in North America, which is the highest level ever recorded during the same time period. These figures represent growth of 14% in units and 10% in dollars over the first nine months of 2016. Automotive-related orders are up 11% in units and 10% in dollars, while non-automotive orders are up 20% and 11%, respectively.

The collaborative robotics market is forecast to reach $4.2 billion by 2023, up from $176.7 million in 2017, achieving a compound annual growth rate of 56.94% between 2017 and 2023, according to ReportsnReports.com. This increase is driven by high ROI rates and the low price of collaborative robots.

Automotive, electronics and metals and machining are the key industries (in terms of market share) in the global collaborative robots market, said the ReportsnReports study. Cobots are used to perform many assembly tasks, which are extensive in the automotive industry.

Cobots with up to 5 kg (just over 11 lb) payload capacity held the largest market share in 2016 and are further expected to lead the market in terms of value and volume between 2017 and 2023. This growth can be attributed to the ease of deployment, adaptability and affordability of cobots.

For a human perspective on this emerging workforce, Melonee Wise, CEO of Fetch Robotics, agreed to share some insights with PlasticsToday in advance of a panel discussion at PLASTEC West.

PlasticsToday: What factors are driving human/robot collaboration?

Melonee Wise: Sensing technology has played a big part in driving down costs to make human-robot collaboration possible. Also, we’ve had to ensure that robots are safe and reliable to work alongside humans. As a business, we’ve been focused on customer needs, the pain points that they have and the tasks that make economic and business sense for robots to do instead of people.

On a larger scale, the vast majority of work done by humans is far too sophisticated for a robot. While the past 10 years have seen a lot of advances in robotics, there are still many tasks that robots can’t do, such as opening a door, going up stairs or working in an unstructured environment. We still don’t have perception systems that can match a toddler in more than one task.”

PlasticsToday: What are the greatest benefits of this type of collaboration?

Wise: Every job comprises dozens of different tasks. If a robot can take over just one of those tasks, that frees up the human to focus on more sophisticated work. In the case of our robots, they take over the task of moving items from one part of a warehouse facility to another.

PlasticsToday: What jobs are best suited for robots and which ones are best suited for human/robot collaboration?

Wise: There are vast swaths of work that are too physically taxing for humans and should be automated through robots or other machines. This has been true since before the invention of the cotton gin. Robots are best suited to take on some limited tasks that humans find boring, repetitive or dangerous. In the logistics industry, where customers are currently buying our robots, the robots are simply a tool to make warehouses more efficient, fill a need where labor is shorthanded and enable [redeployment] of humans to more value-add tasks.

Wise will be joined by David Dechow (Staff Engineer, Intelligent Robotics/Machine Vision, Fanuc America Corp.) and Nicolas De Keijser (Business Line Manager, ABB) in a panel discussion moderated by Rob Spiegel, Senior Editor at Design News, titled “Will Collaborative Robots Ever Replace Human Workers?” on Feb. 7 at 10:15 AM. It is one of several sessions devoted to robotics at the co-located Medical Design & Manufacturing (MD&M) and PLASTEC West trade show and conference coming to Anaheim, CA, from Feb. 6 to 8.

Register now and enter promo code PLASTICSTODAY to receive a 20% discount on conference sessions.

About the Author(s)

You May Also Like