Fipa develops custom gripper system for removing hot plastic parts from injection molding machines

Automated gripper system improves quality of automotive lighting reflectors while accelerating cycle time.

November 1, 2016

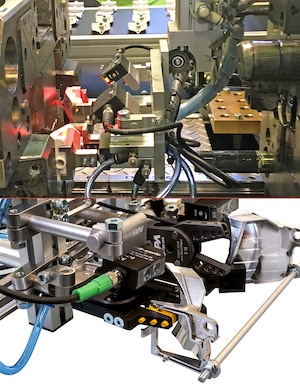

Fipa Inc. (Cary, NC), a manufacturer of advanced vacuum technology, gripper systems, air nippers, tube lifters and end-of-arm tooling (EOAT), recently developed a custom gripper system for an injection molding machine dedicated to making automotive lighting reflectors.

Designed for Zeibina Kunstoff-Technik GmbH, a German plastics processor based in Puschwitz, Fipa’s custom gripper system automated what had been a manual demolding process to protect employees from handling 120o C plastic parts and improve quality by ensuring that parts are removed from their molds free of any marks or paint-wetting defects that could interfere with subsequent coating processes. The new gripper system also successfully reduces cycle time to a succinct 33 seconds, considerably increasing factory throughput.

Designed for Zeibina Kunstoff-Technik GmbH, a German plastics processor based in Puschwitz, Fipa’s custom gripper system automated what had been a manual demolding process to protect employees from handling 120o C plastic parts and improve quality by ensuring that parts are removed from their molds free of any marks or paint-wetting defects that could interfere with subsequent coating processes. The new gripper system also successfully reduces cycle time to a succinct 33 seconds, considerably increasing factory throughput.

“After the lighting reflector blanks are removed from the injection molding machine, they’re transported to another system that coats the plastic parts with vaporized aluminum and other metals to ensure high surface stability,” said Dirk Zeibig, Managing Director at Zeibina. “For this process to be a success, the parts must be absolutely pristine, which proved too challenging for an off-the-shelf solution.

“Fipa has helped us master several other complicated handling challenges over the last few years, so there was no question that we would once again entrust them with the design, development and installation of our latest custom gripper application. The combination of their robust, reliable components, technical expertise, approachable pricing and attentive customer service allows us to further enhance both our quality and competitiveness,” said Zeibig.

About the Author(s)

You May Also Like