Injection molder Tennplasco invests in collaborative robots, achieves ROI in less than four months

Struggling to fill open positions, the custom injection molding company recruited Sawyer, a collaborative robot developed by Rethink Robotics (Boston). As a result, Tennplasco (Lafayette, TN) increased productivity and efficiency and gained a competitive advantage in the injection molding market.

October 6, 2017

Manufacturing companies across the country are continuing to have trouble finding skilled and semi-skilled workers to fill open positions, and the plastics processing industry is no exception. Just ask Danny Rose, General Manager at Tennplasco, a custom injection molding company and division of Manar Inc., located in Lafayette, TN.

“Like many other manufacturers out there, we have been struggling to get workers in our factory, especially on the off shifts,” said Rose. “The truth is, there are not a lot of people in our area looking for injection molding jobs, and if we don’t have people showing up to work, we can’t operate.”

|

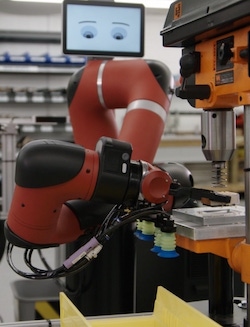

Rethink Robotics' Sawyer gets busy. |

That’s where Rethink Robotics (Boston) came into play. Just three and a half months after deploying Rethink Robotics’ Sawyer robots, Tennplasco has increased its productivity and efficiency, giving the company a competitive advantage in the injection molding market.

“With Sawyer, we don’t have to worry about whether the shift will be staffed, and we can stop wasting our time and effort on trying to recruit non-existent labor,” said Rose.

Easy to deploy with minimal training necessary, Sawyer integrated seamlessly with Tennplasco employees and helped the team design a more efficient work cell.

Rose explained to PlasticsToday that the company first deployed a Sawyer robot in an assembly cell. “We had four people in the cell per shift,” said Rose. “With Sawyer’s help, we have been able to reduce that to two people per shift and re-assigned the other employees.”

Sawyer is being used on the assembly line to help assemble and inspect automotive parts. Automotive component production such as sensors, defrosters and electronics are ideally suited for collaborative robots, and Tennplasco is one of many leading manufacturers using Sawyer for these types of tasks, said Rethink Robotics.

“The area in which Sawyer is deployed requires a little more skill set than our normal floor operators,” said Rose. “We struggled for months trying to keep the off-shifts staffed correctly to meet demand. With Sawyer’s help, we have been able to keep a consistent staff in the assembly area.”

Founded in 1985 in Carthage, TN, Tennplasco offers plastic injection molding services. A division of Manar Inc., Tennplasco currently operates 14 injection molding machines ranging from 150 to 2,000 tons, and employs about 165 people. The company offers secondary operations that include decorating, painting (three automated paint lines) and assembly.

“For small- to mid-size manufacturers, selling the CFO on the cost of deploying automation can be a challenge,” said Rose. “Our team was willing to try it, and with Sawyer, we reached our ROI in just three and a half months. Our customers, especially those in the automotive industry, trust us to support their businesses and meet their changing needs, but to do this, we need both workers and the technology to innovative and be nimble—Sawyer has made that possible.”

Jim Lawton, Chief Product and Marketing Officer at Rethink Robotics, noted that, “globally, manufacturers are facing labor shortages; in fact, Deloitte projects a shortage of two million factory employees by the year 2025. Sawyer gives companies like Tennplasco the tools to stay innovative and competitive in a world where customers have changing needs, and manufacturers need to minimize uncertainty.”

Collaborative robots are able to automate 90% of tasks that, until now, were beyond the reach of traditional automation, according to Rethink Robotics. Its Baxter and Sawyer robots adapt to real-world variability, can change applications quickly and perform tasks like people do, said the company. The result is that manufacturers of all shapes, sizes and industries get the fast-to-deploy, easy-to-use and versatile automation solution they need to increase flexibility, lower cost and accelerate innovation.

About the Author(s)

You May Also Like