Water-Based Surface Treatment Slashes Plastics Prep Time by More Than 90%

Thermoset and thermoplastic resins can be coated without the need for sanding.

April 20, 2021

Oxford Advanced Surfaces (OAS), a pioneer and market leader in the surface preparation of plastic and composite components for painting and lacquering, has developed a new treatment that reduces surface preparation time by more than 90% compared with the existing approach of sanding. Kotefast is available in a water-based formulation, avoiding the need to use solvents in the workplace. The solution can be used with thermoset resins such as polyester, epoxy, polyurethane, vinyl ester, and phenolic, and is equally suitable for treating engineering plastics such as polyamide, polyimide, PC-ABS, and PEEK.

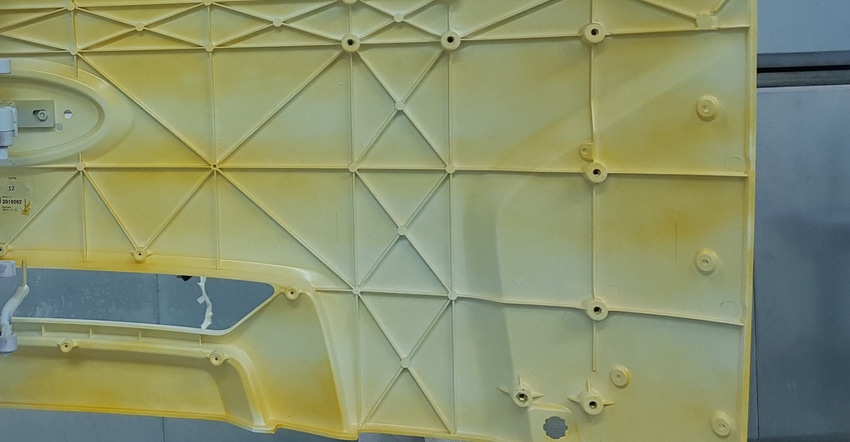

Kotefast was tested on a polyester truck panel (see photo) and the treatment time took less than 15 minutes. An identical panel took three hours to prepare via the usual method of manual sanding, indicating a time saving of more than 90%.

Kotefast also delivered a significant improvement in quality, enabled by the high degree of consistency using its straightforward spray application process. The adhesion of the paint or coating to the substrate is greatly improved as Kotefast chemically bonds to both using the company’s proprietary Onto technology.

Further, Kotefast’s easy application by spray allows even difficult areas, such as internal corners, angles, and blind voids, to be easily prepared. This results in an improved quality finish compared with sanding, including on complex parts.

As well as being available in a water-based formulation, Kotefast avoids environmental challenges that arise with sanding, such as dust which is a potential health hazard for staff. Sometimes the sanding operation needs to be separated from the rest of the production processes, even needing its own building.

“Having a water-based treatment that reduces surface preparation time by 90% could be a game changer,” said Dr Jon-Paul Griffiths, Chief Technology Officer. “At a stroke, we have improved efficiency and productivity in the preparation of plastic and composite parts for painting and lacquering.

“Kotefast has been tested rigorously and is already being used by two OEMs, and we are now working closely with other OEMs and customers to plot a course for its full integration.”

Within reason, there are no time limits of the surface activity when using Kotefast, according to Oxford Advanced Surfaces. Materials can be treated efficiently in batches and then used over a period of weeks or months. Kotefast also supports volume manufacturing of composites reinforced with glass- and carbon-fiber, and molding processes such as sheet molding compound (SMC) and resin transfer molding (RTM), either in or out of autoclave. In fact, its application is independent of the molding process, said Oxford Advanced Surfaces.

About the Author(s)

You May Also Like