JEC Composites Innovation Awards: Finalists in Automotive & Road Transportation — Process Category

Weav3D, Teijin, and Röchling are named finalists.

January 18, 2024

At a Glance

- Composite lattice maximizes performance, minimizes trim waste

- Complex preforms achieve crash-performance requirements with less carbon fiber

- Reactive thermoplastic pultrusion produces cost-effective polyamide composites

The 2024 edition of the JEC Composites Innovation Awards has kicked off with the naming of three finalists per category. The awards ceremony will take place in Paris on Feb. 8, 2024. Here we profile the successful entries in the Automotive & Road Transportation — Process category.

Cost-effective automotive body structures

Company: Weav3D (US)

Partners: Altair Engineering (US), Braskem America (US), Clemson University (US)

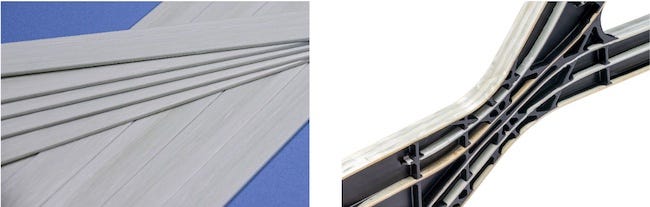

Image courtesy of Weav3D

Description: Weav3D’s composite lattice reinforcement enables lighter and lower-cost thermoplastic solutions than conventional organosheet, unlocking new opportunities for cost-effective replacement of sheet-metal structures with thermoplastics, as demonstrated through this innovative belt-line stiffener door component.

Weav3D’s patented continuous composite forming process enables variable tape spacing, converting glass- and carbon-fiber-reinforced polypropylene (PP) unidirectional tapes (Udmax and Tafnex, respectively) into an optimized, woven, consolidated lattice. This maximizes performance in critical load regions while minimizing trim waste. The innovative door component was manufactured by laminating Weav3D’s lattices to Braskem’s extruded bio-based grade TI4003F PP sheet using a continuous double-belt press, followed by thermo-compression molding the sheet in a matched-metal tool at the Clemson Composite Center and final part trim via 5-axis waterjet.

Key benefits

50% cost savings and 23% weight reduction compared with CF-PA 6 organosheet

62% reduction in trim scrap by weight

Improved energy absorption and shape recovery compared to steel

High-rate automated forming cycle

Made of bio-based PP

Automated preforming process for complex CFRP part

Company: Teijin Automotive Technologies (France)

Partners: Porsche AG (Germany), Airborne (Netherlands), Pinette PEI (France)

Image courtesy of Teijin

Description: A fully automated process for fabricating complex preforms achieves crash performance requirements while reducing the amount of carbon fiber used. Integrated sensors and vision systems provide high accuracy.

The process starts with highly precise cutting of patches and optimized nesting, which is automatically adapted if a defect is detected. The robot stacks the plies, and spot-welding stabilizes the 2D preforms. Each ply is scanned to ensure accurate placement within a 0.5-mm tolerance. The stacking is then heat-activated and consolidated prior to forming. The proprietary 3D concept manages the proper holding of the various layers during the molding phase to ensure final accuracy of the geometry and required thicknesses.

Key benefits

Assembly of several free-form patches in 2D that are then 3D-formed in one step

Accurate positioning of each layer using high-resolution vision systems

Fast, fully automated process ensures repeatability and optimum quality

System is digitally controlled; all plies are scanned to ensure quality

Flexible process is compatible with all types of fibers

Reactive PA6 pultrusion

Company: Röchling Automotive SE (Germany)

Partners: Fraunhofer Institute for Chemical Technology ICT (Germany), Röchling Industrial SE & Co. KG – Haren (Germany)

Image courtesy of Röchling

Description: Reactive thermoplastic pultrusion enables the production of cost-effective and highly resilient automotive components. The profiles are integrated in the final part by injection or compression molding. The polyamide (PA) 6–based composite allows simple recycling without dismantling. The innovation is the use of in-situ pultruded glass-fiber-reinforced PA 6 profiles for cost-efficient composite parts in the automotive industry. The combination of highly efficient production for the reinforcement elements by using continuous pultrusion with state-of-the-art injection molding reduces cycle times and costs. The achievable fiber content of the pultruded profiles is higher than for alternative reinforcements. Because the same plastic material is used for injection molding and the pultruded profiles, the whole part can be recycled without disassembly.

Key benefits

Low-cost processes and raw materials

Single-polymer sustainable solution

Strong and lightweight

Flexibility for diverse applications

About the Author(s)

You May Also Like