JEC Composites Innovation Awards: Finalists in Equipment, Machinery, and Heavy Industries Category

The heavy hitters that made the final cut in this category are Synthesites, AgriLight, and Leitz.

January 30, 2024

At a Glance

- Smart mold controls resin transfer molding process in optimal and automated manner

- Monocoque carbon-composite chassis improves agricultural machinery’s sustainability profile

- CFRP enables development of modular cutting tool for woodworking machine

The 2024 edition of the JEC Composites Innovation Awards has kicked off with the naming of three finalists per category. The awards ceremony will take place in Paris on Feb 8, 2024. Here we profile the successful entries in the Equipment, Machinery and Heavy Industries category. Finalists in several other categories are featured on the PlasticsToday Automotive & Mobility page.

Automatic composites molding system

Company: Synthesites (Greece)

Partners: Safran Composites (France), Safran Tech (France)

![Synthesites1-650x488[83].jpg Synthesites1-650x488[83].jpg](https://eu-images.contentstack.com/v3/assets/blt08823f5db61ded5d/bltede83c4bcc9103ff/65b921eab92085040a75558f/Synthesites1-650x488[83].jpg?width=700&auto=webp&quality=80&disable=upscale)

Image courtesy of Synthesites

Description: A fully sensorized intelligent mold capable of controlling the resin transfer molding process in an optimal and automated manner was developed by Synthesites, Safran Tech, and Safran Composites. The tool incorporates intelligent sensors that can accurately monitor the resin flow, viscosity, glass transition temperature, and degree of cure.

The tool is applicable to industrial resin transfer molding (RTM) aerospace applications, with durable sensors that work in direct contact with carbon fibers; a proprietary calibration technology for the accurate estimation of the resin’s viscosity, degree of cure, and Tg; inline cure sensors for online resin viscosity in the pipelines; and the Cure Simulator to simulate curing only by temperature. This technology can reduce molding time by at least 15% while ensuring part quality.

Key benefits

Online quality control

Reduced injection time

Reduced curing time

Improved part quality

Reduced scrap

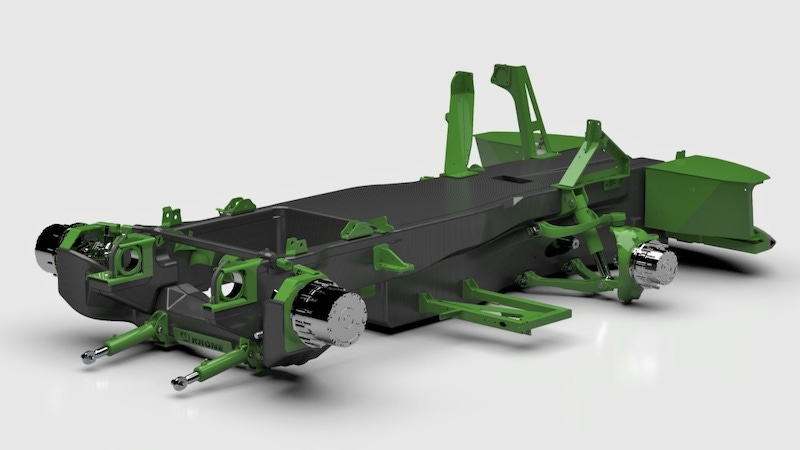

First carbon chassis for large agriculture machine

Company: AgriLight – Research Group (Germany)

Partners: Leibniz University Hannover, Institute of Production Engineering and Machine Tools (Germany); MD Composites Technology GmbH (Germany); Maschinenfabrik Bernard Krone GmbH & Co. KG (Germany); Clausthal University of Technology, Institute of Polymer Materials and Plastics Engineering (Germany)

![AgriLight-650x376[4].jpg AgriLight-650x376[4].jpg](https://eu-images.contentstack.com/v3/assets/blt08823f5db61ded5d/blt090c21fbd77dc906/65b922752482fe040bb589a1/AgriLight-650x376[4].jpg?width=700&auto=webp&quality=80&disable=upscale)

Image courtesy of AgriLight

Description: A novel, function-integrated monocoque chassis in lightweight thermoset carbon composites designed for more sustainable agricultural machinery is fabricated using cost-effective vacuum infusion. This innovation is a carbon chassis for the Krone Big X forage harvester. With a monocoque weight of around 300 kg (661 lb), weight savings of more than 500 kg (1,102 lb) are possible compared to a steel frame. The chassis is manufactured in open molds with vacuum infusion and cured in an oven. With the new design, the tanks are integrated into the closed chassis to further reduce weight and the risk of embers. Despite the weight savings, the chassis has a significantly higher torsional rigidity.

Key benefits

Reduction of fuel and CO2-emissions

Simplified registration for public roads

Lower fire risk due to closed surface

More tank volume due to integration

Higher torsional and bending rigidity

Maximum mass reduction of cutting tools

Company: Deutsche Institute für Textil- und Faserforschung Denkendorf (Germany)

Partner: Leitz GmbH & Co. KG (Germany)

![Leitz-650x488[82].jpg Leitz-650x488[82].jpg](https://eu-images.contentstack.com/v3/assets/blt08823f5db61ded5d/bltc0ecea952ac5fa47/65b922e9e72ce8040a2645a1/Leitz-650x488[82].jpg?width=700&auto=webp&quality=80&disable=upscale)

Image courtesy of Deutsche Institute für Textil- und Faserforschung Denkendorf

Description: A new modular cutting tool for a woodworking machine was developed using the mechanical advantages of carbon-fiber-reinforced plastic (CFRP). A more than 50% weight reduction and increase in working speed of over 50% is achieved. Instead of replacing the metal tool body with CFRP, new design principles were analyzed using numerical simulation. Following the principle of optimal load sharing, the virtual development resulted in a modular tool design, with triangular components that absorb the centrifugal forces and an outer shell that accommodates the bending and torsional loads. Load-optimized orientation of carbon fibers leads to maximum stiffness and strength of the tool body. The final result features maximum weight reduction and increased productivity without compromising product quality.

Key benefits

Modular lightweight design with CFRP parts can replace standard cutting tools

New design exploits fiber strength and stiffness leading to rigid tools

Over 50% mass reduction and 50% higher speed and productivity are possible

Scalability of design leads to a high application range

Usage with standard adapter and cutting knives, high processing accuracy

About the Author(s)

You May Also Like