Nissan Claims Breakthrough in Carbon-Fiber Part Production

New process cuts development and cycle times for components that make cars safer, more fuel efficient, and fun to drive.

September 9, 2020

Nissan Motor’s Green Program aims to reduce CO2 emissions by 40% in 2022 and by 90% in 2050. Besides moving to hybrid and electric powertrains, the automaker sees lightweight body development as a key component in achieving these cuts, with mass production of carbon-fiber-reinforced plastic (CFRP) parts a key enabling technology.

With full-scale deployment planned for 2025, Nissan recently announced the development of a cost-effective technology for molding CFRP components in minutes rather than the hours required using autoclave. Nissan’s compression resin transfer molding (C-RTM) process can turn out parts in two minutes versus 10 minutes for conventional RTM and 180 to 240 minutes for the autoclave process.

|

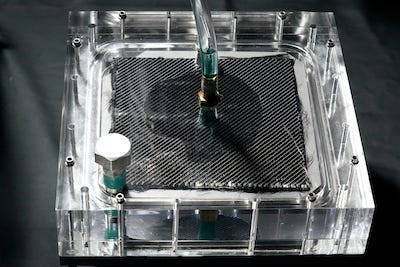

A transparent test tool incorporating pressure and temperature sensors was used to assist in development |

Crucial in development of this C-RTM process was development of a simulation tool to accurately predict resin impregnation of the carbon fibers, thus significantly reducing product development time versus the trial and error method of days before, as well as cycle times. “The innovation can cut the lead time to develop such components by as much as half, and cycle time for molding by about 80%, compared with conventional methods,” says Nissan

Nissan also overcame technical challenges such as wrinkles and deformation occurring when the carbon fiber sheet is pressed and the need for full impregnation before the resin hardens.

Besides lightweighting, Nissan says a car’s center of gravity can be lowered when CFRP is applied to upper body parts, making it more agile and exciting to drive.

About the Author(s)

You May Also Like