Polymers Key Enablers in Driver Assistance Systems

Radar-permeable polymers are hydrolysis-stabilized, dimensionally stable, and cost effective to process using laser transmission welding.

August 11, 2022

Modern cars are equipped with advanced driver assistance systems (ADAS) and enabling sensors in ever-increasing numbers. ADAS improve the safety of all road users and are paving the way for highly and fully automated driving. According to German statistics platform Statista, the ADAS market will reach a value of $32 billion in 2023. Annual growth of 17% is forecast.

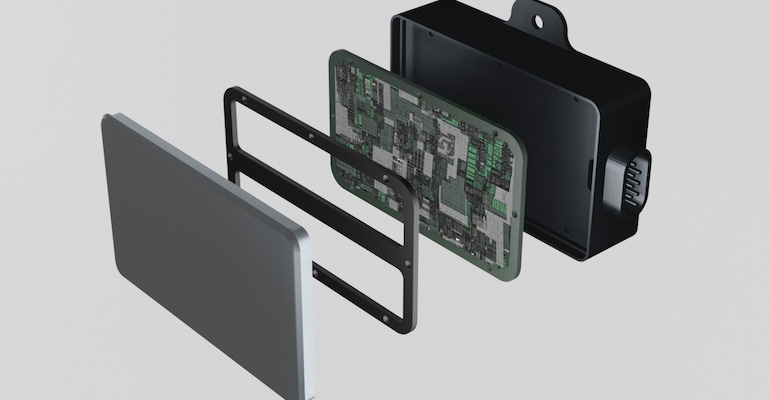

“ADAS radar sensors and their housings, in particular, are an attractive field of application for our polybutylene terephthalate (PBT) and polyamide compounds,” explained Christopher Hoefs, ADAS expert at the High-Performance Materials (HPM) business unit at Lanxess. “We have a wide product range that meets the desired technical requirements for this area. These include good radar transparency and dimensional stability, good laser welding behavior, and also excellent mechanical properties for fastening the sensors in the vehicle safely and durably,” said Hoefs.

ADAS sensors monitor the entirety of a vehicle’s surroundings. Their operation is based on electromagnetic waves such as radar or laser beams (LiDAR), ultrasound or imaging techniques, which have a significant bearing on the material chosen for the sensor housing. For example, it is essential for the front of a radar sensor housing, also referred to as the radome, to be permeable to radar beams. To minimize radiation losses, the material for the radome must have a low dielectric constant (Dk) and loss factor (Df).

For this purpose, Lanxess has carried out extensive tests on numerous compounds in its range, including measurements of one-way attenuation and specific transmission and reflection as a function of frequency and material thickness. “We have numerous PBT types with Dk and Df values that make them suitable for use with the ADAS radar frequencies of 77 to 81 gigahertz that are increasingly being used,” said Hoefs.

Depending on where the sensor is installed, the plastic for the housing must be resistant to hydrolytic degradation. With the Pocan XHR series, Lanxess has PBT compounds that achieve the top Class 4 or Class 5 ratings in the stringent SAE/USCAR2 Rev. 6 long-term hydrolysis tests of the US Society of Automotive Engineers (SAE). At the same time, they are resistant to hot air and exhibit high elongation at break values.

The compounds from the Pocan HR series are suitable for less-demanding hydrolysis stability requirements. These include the fiberglass-reinforced Pocan B3233HRLT compound, which is both transparent to lasers and resistant in hot and humid environments, which are usually mutually exclusive properties. “This material is very well suited to joining housing components of radar or camera sensors cost-effectively using laser transmission welding, for example,” said Hoefs.

Lanxess assists manufacturers of ADAS technologies with an extensive range of HiAnt services, ranging from joint concept development for the design of components and material optimization to cutting-edge methods in computer-aided engineering (CAE) for precisely predicting mechanical and thermal properties of components. “We also provide our partners with material data. For example, in addition to the respective Dk and Df values of compounds, developers of radar sensors receive data on the relationship between the specific transmission and reflection on the radar frequency and test body thickness,” explained Hoefs.

Lanxess will showcase these and other developments at K 2022 in Düsseldorf, Germany, on Oct. 19 to 26, 2022. The company will exhibit in booth C76-78 in hall 6.

About the Author(s)

You May Also Like