Zeiger Industries teams up with seven partners to mold LED headlamp optic at NPE2018

The part will be molded from Dow’s Dowsil MS-4007 silicone on a Milacron-Fanuc Roboshot machine. M.R Mold & Engineering, Elmet, Thermal Care, Yushin and SigmaSoft also contributed their expertise to the demo.

April 13, 2018

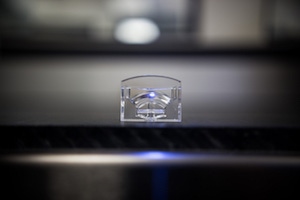

Zeiger Industries (Canton, OH), a manufacturer of plasticating components such as screw tips, tool-steel screws and nozzles, has teamed up with seven other companies to showcase the molding of an automotive LED headlamp optic at NPE2018 in booth W4143.

Zeiger Industries (Canton, OH), a manufacturer of plasticating components such as screw tips, tool-steel screws and nozzles, has teamed up with seven other companies to showcase the molding of an automotive LED headlamp optic at NPE2018 in booth W4143.

The part will be molded from Dow’s Dowsil MS-4007 moldable silicone on a Milacron-Fanuc Roboshot a-S55iA fitted with a new iHMI controller. The two-cavity mold was built by M.R. Mold & Engineering with a single-drop cold-runner system. The production cell also will utilize an Elmet TOP 5000P dosing system; a Thermal Care air-cooled EQ34A01 portable chiller; and a Yushin YC-100S-11-8 robot with an E-Touch Compact controller, custom end-of-arm tool and Yushin indexing conveyor. A virtual molding simulation of the filling and curing process will be provided by SigmaSoft.

Zeiger Industries’ LSR Plug-n-Play Conversion Kit is an economical way for thermoplastic molders that have excess capacity to either enter the LSR molding field or increase LSR machine capacity by simply switching out their existing thermoplastic plasticizing unit with the kit.

Zeiger’s Plug-n-Play Conversion Kit incorporates a Wexco 777 water-cooled barrel, Zpringlok LSR pre-closed check ring valve, ZSAR PM zero compression ratio LSR screw and proprietary barrel/screw sealing device.

The Dowsil MS-4007 material, like the rest of the Dowsil Moldable Optical Silicone portfolio, (obtained through distributor R.D. Abbott Company Inc.), is designed to perform in demanding environmental conditions and enables complex optic designs that cannot be replicated with more rigid materials, said the company.

About the Author(s)

You May Also Like