5 Bioplastics That Meet Today's Food Packaging Needs

Three drop-in bio-derived replacements for fossil-fuel-sourced polymers and two enhanced-barrier polymers made from biomass provide brands with responsible packaging options.

September 12, 2023

Two major drivers — fluctuating oil prices and brand and retailer commitments to United Nations SDG Target 12 — are fostering the substitution of fossil-derived with bio-derived polymers in the food industry.

Fortunately, this makes sense for all stakeholders. In bio-derived polymers, fossil-derived fuel can be replaced by biomass to supply the building blocks for polymer synthesis. In fact, using nonfood products such as agricultural waste as the source of biomass for bioderived polymers is critical. When bio-derived plastics are sourced from human (especially) or animal food crops, forest issues including biodiversity loss, water use, and land use arise.

It's interesting that lignin, a by-product of paperboard manufacturing, can also be used as a feedstock for bio-derived polymers.

In light of circularity and material efficiency, bio-derived polymers that can be reused or recycled are more sustainable than those that biodegrade.

Three bio-derived “drop-in” polymers for food packaging.

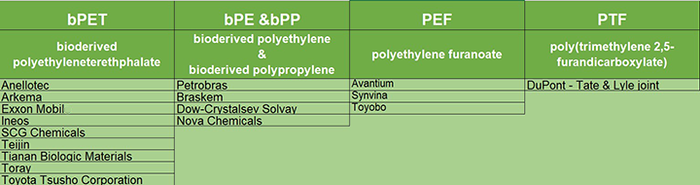

Bio-polyethylene (bPE), bio-polypropylene PP (bPP), and bio-PET can replace fossil-derived polymers.

The pricing of bio-derived polymers is oddly linked to the fossil fuel industry. For example, bPE pricing fluctuates with gas prices because it competes with bioethanol car fuel that is used more often when fossil fuel prices are high. Because of a 2021 innovation that produced terephthalic acid (TPA) from bio-sourced paraxylene, 100% bPET is now attainable.

For example, this is an improvement above Coca-Cola's 2009 30% bioderived Plant bottle. With more than 15 global producers generating bio-derived paraxylene, the market for bPET is predicted to grow from $441.3 million in 2021 and above the current 10% of annual EU PET output, according to an Allied Market Research report.

One bPET example is Toray Plastics' dual-ovenable LumiLid, which contains 50% bPET in conjunction with a bio-based adhesive.

Two more bio-derived food packaging options with better barriers.

Two others, bioderived polyethylene furanoate (PEF) a 100% recyclable bioplastic PEF and polytrimethylene furandicarboxylate (PTF), provide better barriers.

Interestingly, patents for both PET and PEF were issued in 1946. PEF bioplastic provides a superior barrier to PET. Current use of PEF for food packaging includes:

Carlsberg's Green Fiber Bottle paper-based bottle is made from wood fiber and lined with a thin layer of PEF from Avantium starting in 2024.

Danone's evian+ flavored mineral water beverage100% recycled PET with small amount of PEF.

PTF is supported by a DuPont - Tate & Lyle joint venture in Tennessee.

Consumer education is critical to convey that polymers can be made from bioderived sources and reused and recycled.

Further information on bioderived packaging options.

Claire Sand has 30+ years of experience in industry and academia. She’s owner of Packaging Technology and Research and Gazelle Mobile Packaging and an Adjunct Professor, CalPoly, Michigan State University, and the University of Minnesota. You can reach her at www.packagingtechnologyandresearch.com or [email protected].

About the Author(s)

You May Also Like