Electric Cold Runner Moves the Needle on LSR Molding

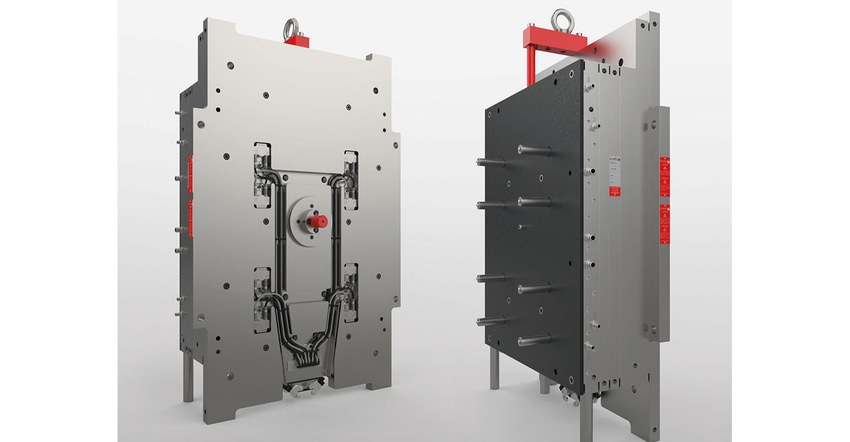

Elmet’s SMARTshot E for liquid silicone rubber (LSR) multi-cavity injection molding features rapid, servo-driven needle positioning to an accuracy of 0.002 mm.

October 22, 2021

Austria’s Elmet has introduced an all-electric SMARTshot E valve-gate cold runner system with servo-driven nozzle needles. The architecture reportedly maximizes flexibility and precision when injecting two-component liquid silicone rubbers (LSRs) into multi-cavity molds.

Compact, brushless DC servomotors move and position the needles of the SMARTshot E as the nozzle opens and closes. An 18.5-in. color display allows rapid and consistent needle positioning to an accuracy of 0.002 mm. Thanks to opening and closing times on the order of hundredths of a second, needle movements can be perfectly synchronized and precisely balanced during injection in up to 16 cavities. The low waste-heat output and small space requirements of the servomotors enable compact mold designs — nozzle spacing has been reduced to as little as 44 mm.

The SMARTshot E is connected via virtually wear-free miniature industrial connectors capable of withstanding frequent assembly and disassembly. Optimized cable management with a cable harness enable easy removal as an assembly without requiring a qualified electrician. The harness also prevents incorrect connection upon reassembly. Clear recipe management with import and export options as well an integrated authorization system with user management also maximizes operating reliability, according to Elmet.

The SMARTshot E complements its range of SMARTshot liquid injection molding cold runner systems, said Elmet. All SMARTshot models allow individually defined calibration and filling behavior for each nozzle. They also have a particularly long needle guide and complete protection from needle twisting — the tip of the needle is part of the molding cavity contour. The cooling system and thermal isolation of the cold runner from the mold side ensure process stability. The applied molding principle ensures almost complete elimination of production waste, such as sprues and runner scrap, according to Elmet.

About the Author(s)

You May Also Like