Additive replaces talc in filled PP auto parts, helps them lighten up

Automobiles will remain on a forced diet for the foreseeable future opening up opportunities for a variety of suppliers to help cars lighten up. Among those entering the fray is additive supplier Milliken Chemical, which touted what it calls a synthetic reinforcing agent at NPE2012, saying the product can replace talc in filled polypropylene automotive interior applications, helping a door panel at the show shed 10% of its weight.

April 24, 2012

Automobiles will remain on a forced diet for the foreseeable future opening up opportunities for a variety of suppliers to help cars lighten up. Among those entering the fray is additive supplier Milliken Chemical, which touted what it calls a synthetic reinforcing agent at NPE2012, saying the product can replace talc in filled polypropylene automotive interior applications, helping a door panel at the show shed 10% of its weight.

Milliken Chemical Hyperform 803i |

Milliken Chemical Hyperform 803i |

Visitors to Milliken's NPE booth were greeted by three injection molded TPO door panels, each one lighter than the next, thanks to the replacement of talc with Hyperform HPR 803i.

The first panel, which was 20% talc filled, weighed in at 1693g, while the final and lightest panel, weighing in at 1543g, had only 9% talc, with that filler replaced by Hyperform HPR 803i, cutting the part's weight by almost 10%.

Adam Watson, global product line manager for plastics additives at Milliken, told PlasticsToday that HPR-803i can be used alone or in combination with talc to deliver improved scratch performance, good mechanical performance and excellent heat resistance, in addition to lighter parts. At this time, several OEMs are undertaking final material approval for the technology, with Milliken hoping to source the additive into automotive in upcoming fleets.

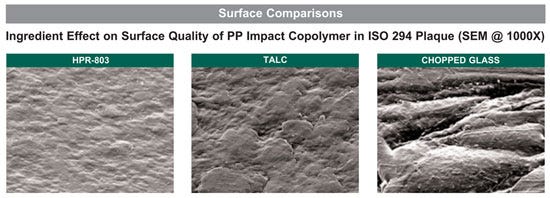

In addition to weight reduction, Milliken says the additive has improved surface finish versus glass, as well as improved colorability, derived from its bright white hue.

About the Author(s)

You May Also Like