Has the Sustainable Packaging Ship Sailed?

With increased pressure to reduce plastic waste, there’s only about a two-year window for new technologies to gain recognition and broad implementation.

April 10, 2023

Why do we have internal combustion engines, rather than steam engines, which produce less pollution and provide the same simplified and exhilarating driving experience of electric vehicles?

Why was our original nuclear power technology based on light water rather than heavy water reactors, when the latter are more efficient?

Why were most tape cassettes produced in the VHS format, when the Betamax format produced clearly superior results?

The answer in all three cases is known as “lock-in”, which occurs when an inferior technology wins the battle of market share, effectively removing the superior technology from the marketplace (at least for a while).

In the case of internal combustion engines, Henry Ford’s unstoppable desire and assembly line mentality assured that this technology, which was far cheaper than steam technology, would win the day…at least until Elon Musk came along.

In the late 1940s, Admiral Hyman Rickover was tasked with building a nuclear navy as fast as possible, thus reducing the threat of potential Soviet military submarine superiority. He reached for “off the shelf” light water technology, which was both proven and accessible, rather wait to test and approve newer more efficient heavy water technologies. Thus, the first waves of nuclear subs and aircraft carriers used this less efficient approach to propulsion.

Finally, Betamax was superior to VHS technology in terms of higher resolution, smaller tapes, and a two year go-to-market advantage. But VHS allowed users to initially record up to two hours of TV and then eventually six hours, versus one hour for Betamax. Consumers wanted to see more and pay less, so VHS won.

What this all mean for sustainable packaging and especially plastics?

I mentor or consult with a few companies working on new technologies that are aimed at removing impediments associated with plastics recycling. While conducting due diligence, I called my longtime friend and environmental associate, Emily Tipaldo, who is Executive Director of the U.S. Plastics Pact. For reference, the U.S. Pact calls itself a “solutions-driven consortium” and was founded by The Recycling Partnership and the World Wildlife Fund. It is part of the Ellen MacArthur Foundation’s global Plastics Pact network and connects both public and private stakeholders across the plastics value chain.

After describing the technology involved in my mentoree’s solution for contamination removal in the PET stream, Emily sighed and mentioned other promising plastics recycling technologies that she was aware of as well. After a few more minutes of discussion regarding these new approaches, and the current state of consumer and legislative perceptions, we came to the same conclusion:

Given the tremendous pressure to reduce plastic waste in the very near future, we see about a two-year window for new technologies to gain recognition and widespread planned implementation. Thus, we are probably past the point where potentially superior technologies that will require 7 to 10 years of testing, approval, certification, and funding can be broadly implemented.

The U.S. Pact recommends the elimination 11 specific materials and or applications.

Our thinking on this is very much in line with the U.S. Plastic Pact's Problematic and Unnecessary Materials List, which calls for the elimination of 11 specific materials and/or applications, ironically within two years. As stated on their website, “The 11 items listed are not currently reusable, recyclable, or compostable with existing U.S. infrastructure at scale and are not projected to be kept in a closed loop in practice and at scale by 2025.”

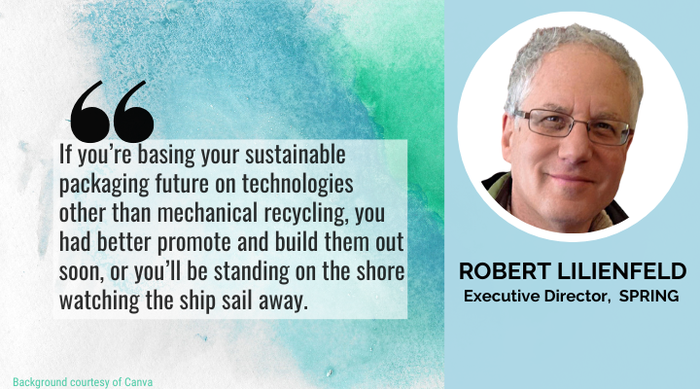

The conclusion from our discussion is straightforward: The only sustainable packaging technology that the public understands and supports, at least vocally, is mechanical recycling. If you are basing your sustainable packaging future on other technologies, you had better promote and build them out soon, or you’ll be standing on the shore and watching the ship sail away.

What about the other strategies in the EPA solid waste pyramid? Because of its cost saving implications, source reduction will always play a large role at industrial and commercial levels, but consumers don’t understand it and literally cannot see it or its value: It happens in the background. Refills and reusables work in some instances, but not all. Compostables, especially plastics, provide little or no actual sustainability value outside a narrow window primarily related to food contact packaging, especially where industrial composting is viable.

Without a nationally orchestrated focus on greenhouse gas reduction and data-based decision making across all material types, the demand for recyclable packaging will continue to ramp up. Ironically, the growing appetite for extended producer responsibility (EPR) legislation will accelerate this trend, as consumers are being led to believe that these systems won’t cost them anything.

Under this scenario, polymers other than PET and high-density polyethylene (HDPE) for beverages and other bottles will begin to disappear, no matter how environmentally efficient and cost effective they really are (hint: low-density polyethylene, polypropylene, and polystyrene).

Paper will continue to make inroads in both rigid and flexible packaging applications. Recycle-friendly coatings and adhesives will gain ground.

Also advancing will be so-called compostable coatings that don’t contaminate the paper recycling stream: The ability to send a paper package to either a recycler or industrial composter is a big perceptual consumer marketing win.

Are we close enough to the tipping point that the recycling hammer becomes the only implement in the sustainable packaging toolbox, and all problems begin to look like nails? It’s sure starting to look that way.

Does this mean that those of you who are plastic packaging developers, producers, and users should give up? Not necessarily. But it does mean that you must start thinking about what you’re selling in a whole different way.

Years ago, when asked for the key to the success of the Revlon business, Charles Revson stated that the company didn’t sell cosmetics. It sold hope.

Maybe you should, too. But this time the hope is for a better, more sustainable world, not simply a sexier shade of lip gloss.

Note: Emily Tipaldo is the Executive Director of the U.S. Plastics Pact, a solutions-driven consortium of more than 100 diverse businesses and organizations across the plastics value chain. Her expertise in sustainable packaging was bolstered by her previous experiences as Director, Strategy and Business Development at MORE Recycling and Director, Plastics Packaging and Consumer Products at the American Chemistry Council.

Robert (Bob) Lilienfeld has been involved in sustainable packaging for 25 years, working as a marketing executive, consultant, strategic planner, editor, writer, and communications expert. He’s President of Robert Lilienfeld Consulting, working with materials suppliers, converters, trade associations, retailers, and brand owners. He is Executive Director at SPRING, The Sustainable Packaging Research, Information, and Networking Group. You can also write him at [email protected] or visit his LinkedIn profile.

About the Author(s)

You May Also Like