BASF commits to vehicle lightweighting via RTM

BASF (Ludwigshafen, Germany) is pouring tens of millions of Euros into a comprehensive research effort to promote the use of composite materials in automobiles, the key processing technology employed being resin transfer molding (RTM).

September 12, 2011

BASF (Ludwigshafen, Germany) is pouring tens of millions of Euros into a comprehensive research effort to promote the use of composite materials in automobiles, the key processing technology employed being resin transfer molding (RTM).

As part of this effort, a lightweight composites team has been established for fast and efficient development cooperation with the automotive industry, and a new lightweight design laboratory has started operations. The primary objective is development of fast curing epoxy, polyurethane (PU) and polyamide (PA) solutions for new fiber-reinforced composite technologies

|

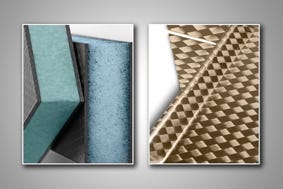

Polyurethane, epoxy and polyamide-base composite materials at core of vehicle lightweighting initiative. |

In mid-2011 BASF established a lightweight composites team. The group focuses on the development of marketable materials and technologies that are suitable for manufacturing high-performance fiber-reinforced parts for automotive applications. More metal can be replaced only through use of lightweight yet strong composite materials and parts, and in this way - regardless of the propulsion system in the vehicle - reduce energy consumption and CO2 emissions even further.

Via its broad product portfolio, BASF is able to investigate three different plastic matrix systems simultaneously and intends to develop tailor-made formulations in close cooperation with customers. "We can build here on BASF's know-how in the areas of epoxy, polyurethane and polyamide chemistry, want to exploit the synergies in the team and will be making a double-digit million euro investment in development in the coming years", explained Willy Hoven-Nievelstein, BASF's head of the Engineering Plastics Europe business unit.

RTM can be used to produce large and complex composite components in a single press-form operation. This involves placing multilayer fiber structures in a heated mold that is mounted in a press. A liquid resin is then injected into the mold, wetting the fibers completely and then curing in a controlled manner. In the newly established RTM laboratory in Ludwigshafen and at PU research in Lemförde, Germany, BASF experts are working on the chemical and technical challenges posed by the new matrix solutions. The automobile components to be produced from these materials in the future will be able to withstand high loads despite their light weight.

In addition to the mechanical performance of the finished fiber-reinforced composite part, good flow characteristics and, above all, a short curing time of the resin components represent the primary challenges with all three material systems. BASF already offers solutions on the basis of epoxy and PU systems under the brand names Baxxodur and Elastolit R, respectively. Epoxy resin systems from BASF are in use today for the rotor blades of wind turbines.

Both solutions employ novel curing mechanisms: thanks to their low initial viscosity, they impregnate the fiber structures very well and then cure within only a few minutes. Thus they address one of the problems that previously represented an obstacle to the use of high-performance composites in automobile production.

They are self-releasing and can be processed on existing high- as well as low-pressure equipment. Moreover, the new PA systems that are currently under development can be welded easily and also recycled as thermoplastics. BASF is devoting significant effort on accelerated curing of the three plastic matrix systems, and thus a further shortening of the cycle time.

Structural chassis or body components can be manufactured only from composite materials based on endless carbon or glass fibers, and require fiber contents of about 65 weight percent. Endless fibers are already in use today in aircraft and wind power applications, in plant construction, in prototype construction and in short-run automotive applications.

Carbon fibers impart very high stiffness as a reinforcing material and are thus of special interest. To interact with application engineers and end users at an early stage, BASF has recently become a member of Carbon Composites e.V. ( (CceV; Augsburg, Germany), a competence network for carbon fibers and fiber-reinforced composite technology that was established in 2007 and now has more than 120 members. In addition to the performance of a reinforcing material, price and availability are important for rapid introduction of matrix systems to the market. Glass fibers show great potential here: The limits of their mechanical strength have not yet been reached by far.

The overall system consisting of plastic matrix and fiber reinforcement must be processable on a reliable basis and readily adoptable for high-volume production. Compared to conventional metal components, they will contribute to a weight reduction of about 50%. Established technologies that embed metal inserts or endless fiber-reinforced thermoplastic mats and UD tape (unidirectional fiber reinforcement) in plastic complement the new approach. In addition, endless fiber-reinforced skin layers can be combined with lightweight foam cores to yield high-quality sandwich structures with exceptionally good specific part stiffness and good insulating characteristics in combination with low weight. The PU foam systems developed for such parts by BASF are characterized by high compressive strength and temperature resistance in conjunction with a low density. "Without such multimaterial systems, the next major advance in lightweight automotive applications will not be possible", states Volker Warzelhan, Head of Thermoplastics Research at BASF.

At the same time, BASF is expanding the capabilities of ULTRASIM, its now universal computer simulation tool, the objective being the ability to predict the behavior of complex endless fiber-reinforced composites as well.-[email protected]

About the Author(s)

You May Also Like