PVC offers low-temperature properties for vehicle charging cables

A new jacket compound that exhibits a low-temperature brittleness value of

May 29, 2014

(Pawtucket, RI). The newest product, Flexalloy 9612-75, is a 75 Shore A jacket compound that complies with the -40 ºC Cold Impact test requirement specified in CSA standards. It exhibits tensile strength of 2,645 psi (18.2 MPa) and elongation of 390%, and it complies with the UL-62 oil resistance requirement.

"All of the Flexalloy compounds for EV charger cable are abrasion resistant, resilient, and tough even at very low temperatures, yet cost-effective for large-volume production," says Michael Roberts, wire and cable industry manager. "The durability and elasticity of Flexalloy PVC elastomers make them high-performance alternatives to standard PVC compounds while being less expensive than premium materials like thermoplastic polyurethane."

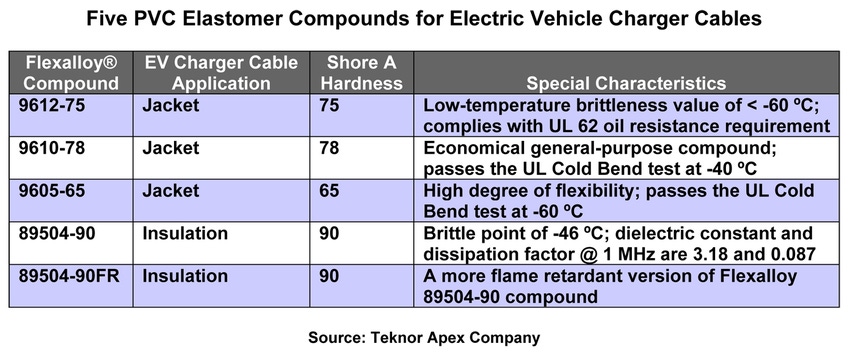

Since introducing its first Flexalloy compound for EV charger cables in 2012, Teknor Apex has continued to expand its portfolio of products for this application (see table). Besides the new Flexalloy 9612-75 compound, others in this family of materials include:

---Flexalloy 9610-78, an economical general-purpose product that can pass the UL Cold Bend test at -40 ºC. This 78 Shore A material has a brittle point of -38ºC; tensile strength of 2,625 psi (18.1 MPa); and elongation of 350%. Flexalloy 9610-78 exhibits a limited oxygen index of 26%.

---Flexalloy 9605-65, a 65 Shore A jacket compound that is even more flexible and is capable of passing the UL Cold Bend test at -60ºC.

---Flexalloy 89504-90, a 90 Shore A insulation compound, and a more flame retardant version, Flexalloy 89504-90FR. Flexalloy 89504-90 has a tensile strength value of 2,830 psi (19.5 MPa), elongation of 340%, and brittle point of -46ºC. It exhibits a limited oxygen index of 27%. Its dielectric constant and dissipation factor at 1 MHz are rated at 3.18 and 0.087.

All of these materials can meet requirements for a maximum continuous operating temperature of 105 ºC.

Unlike standard flexible PVC, Flexalloy compounds are based on ultra-high molecular weight PVC resin. They exhibit improved toughness, abrasion resistance, and low temperature properties and provide elastomeric resilience and resistance to compression set. The compounds can be processed on standard PVC equipment.

About the Author(s)

You May Also Like