Sponsored By

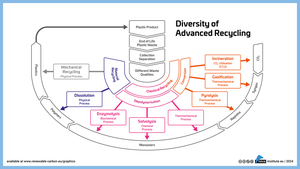

Advanced Recycling

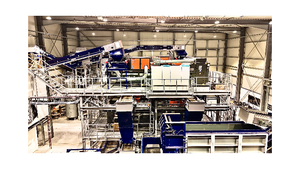

waste-sorting conveyor

Advanced Recycling

Brightmark Plans to Build $1 Billion Plastics Circularity Center in GeorgiaBrightmark Plans to Build $1 Billion Plastics Circularity Center in Georgia

The announcement comes just two years after Brightmark had to scrap a similar project in a different Georgia community.

Sign up for the PlasticsToday NewsFeed newsletter.