Sponsored By

News

Bioplastics-NewsStream-FTR-PT.png

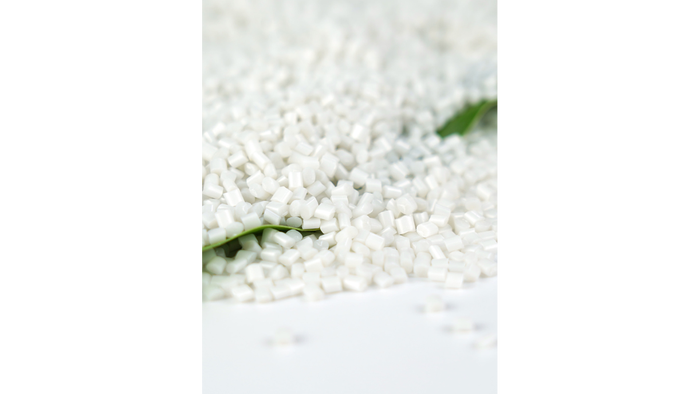

Biopolymers

Bioplastics News StreamBioplastics News Stream

Bioplastics at NPE2024, biopolymers from larvae and crab shells, bioplastics market growing 15.3% yearly, bioplastics questioned in organic compost, BASF and McDonalds partnership.

Sign up for the PlasticsToday NewsFeed newsletter.