Sponsored By

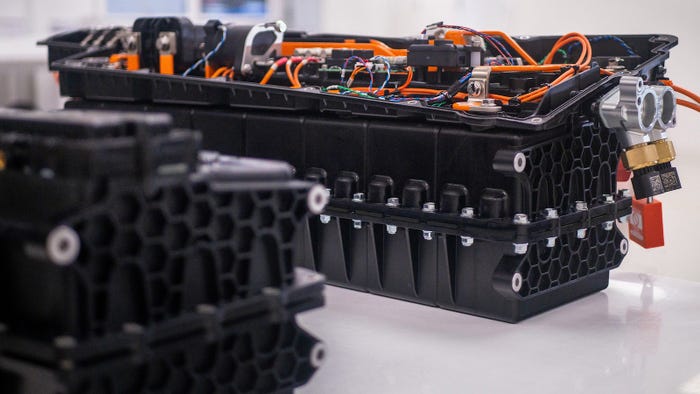

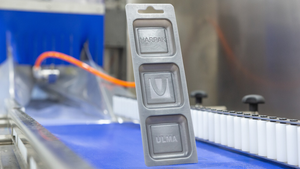

Celanese polyamide used in automotive parts

Automotive & Mobility

A Metal Replacement Star Is BornA Metal Replacement Star Is Born

Celanese introduced a polyamide reinforced with short glass fibers at Chinaplas this week that sets a new bar for lightweight, high-performance automotive materials.

Sign up for the PlasticsToday NewsFeed newsletter.